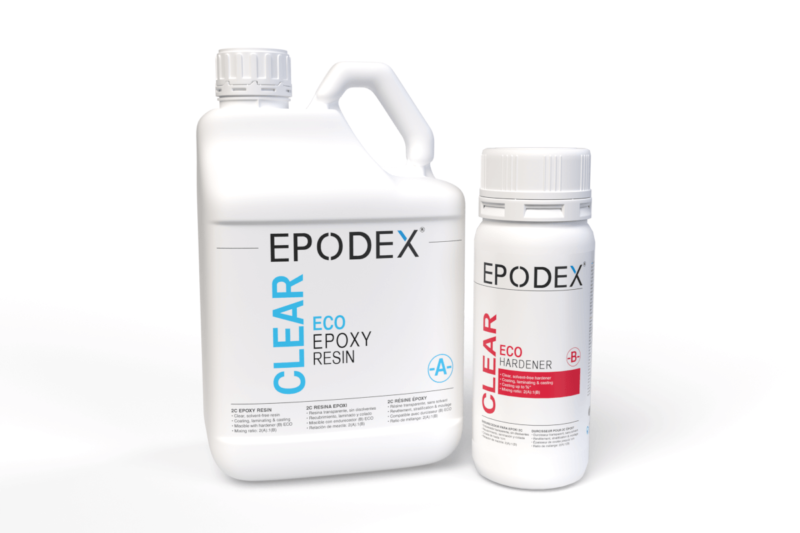

EPODEX – Hardener (without Resin)

The hardener B-component must be mixed with the resin A-component before use. The Epoxy Systems Kits, consisting of resin and hardener, are suitable for a wide range of applications such as civil, electrical and mechanical engineering. It is a classic coating, laminating, and repairing epoxy resin. It can be used as casting resin in layers up to 2″ thick. Coat your floors, tabletops and other objects. Our EPODEX Epoxy System are miscible with all our color pigments.

Instructions for Use

- Always start with an epoxy resin primer to avoid high material loss and blistering (layer thickness: approx. 1/64″ mm). To do so, simply use a portion of the same clear epoxy resin (to prime floors and other colored substrates we recommend to use our water-based epoxy resin EPOXY PRIMER Kit).

- Mix te resin A-component with th hardener B-component in a ratio of 2:1 (e.g. 64oz resin: 32oz hardener).

- Stir through the edge and bottom of the mixing cup as material will settle there. Ideally, pour into a clean mixing cup and mix again until the mixture is streak-free. This ensures that the resin A-component and hardener B-component are completely mixed together.

- Pour the resin-hardener mixture onto the surface to be coated immediately after mixing, as the product can start to boil in the mixing cup.

- Paint the epoxy primer with a paint roller or brush on the desired surface.

- Let the primer cure. The curing time depends on the temperature and the layer thickness. You can find more detailed information in our information table under the the “Learn more” button on this product page.

- Continue with the main coating in the same way. If you select a color on this product page, you will receive dyes or color pigments in addition to the resin and hardener.

- To color the main coating, mix the supplied color with the resin A-component or with resin-hardener mixture. Adjust the color intensity individually by adding more or less color pigments.

Info: Epoxy resin is sensitive to any kind of moisture during curing (risk of amine blush formation, i.e. white patches in the top layer). For this reason, we recommend that you avoid any contact between water and the epoxy until it has cured completely. For thin layers, cold temperatures (ambient, substrate, and resin temperatures below 70°F) and increased humidity, the time until the epoxy resin is fully cured may be extended.

Consumption Volumes

Determine the required amount of resin needed with the help of our epoxy resin “Calculator” on this product page.

Total Thickness for Floors and Other Surfaces: 1/16”

- Priming with ECO: approx. 1oz/sqft

- Priming with EPOXY PRIMER: approx. 0.65oz/sqft

- Main Layer: approx. 4oz/sqft

Quantity of Colorants to Use

- Powder pigments (Metallic, Neon and Glow in the dark): 1g of pigment per 2oz of epoxy. 70g (2.5oz) of pigment per gallon of epoxy,

- Transparent dyes (except white, black and gray): 1g of dye per 17.5oz of epoxy. 7g (0.25oz) of dye per gallon of epoxy,

- Transparent white, black and gray dyes: 1g of dye per 53oz of epoxy. 2.5g (0.1oz) of dye per gallon of epoxy,

- Semi-transparent dyes (except white): 1g of the desired dye and 0.5g of white dye per 26.5oz of epoxy. 5g (0.2oz) of the desired dye and 2.5g (0.1oz) of white dye per gallon of epoxy,

- Semi-transparent white: 1g of dye per 17.5oz of epoxy. 7g (0.25oz) of dye per gallon of epoxy,

- Solid color: 1g of dye per 3oz of epoxy. 40g (1.5oz) of dye per gallon of epoxy),

- Glitter pigments/flakes: 1g of dye per 3oz of epoxy. 40g (1.5oz) of dye per gallon of epoxy

Customer Service: If you have further questions, please contact us by phone, e-mail or use our WhatsApp support.

Note: Please note that due to different lighting conditions and monitors, the colors may not be uniformly displayed. All information is recommendations based on our experience; without legal obligation.