Get the service you deserve!

✓ Guaranteed hassle-free shopping experience. Simply select the color and the epoxy quantity you want. We automatically calculate the required amount of colorant to dye the clear epoxy.

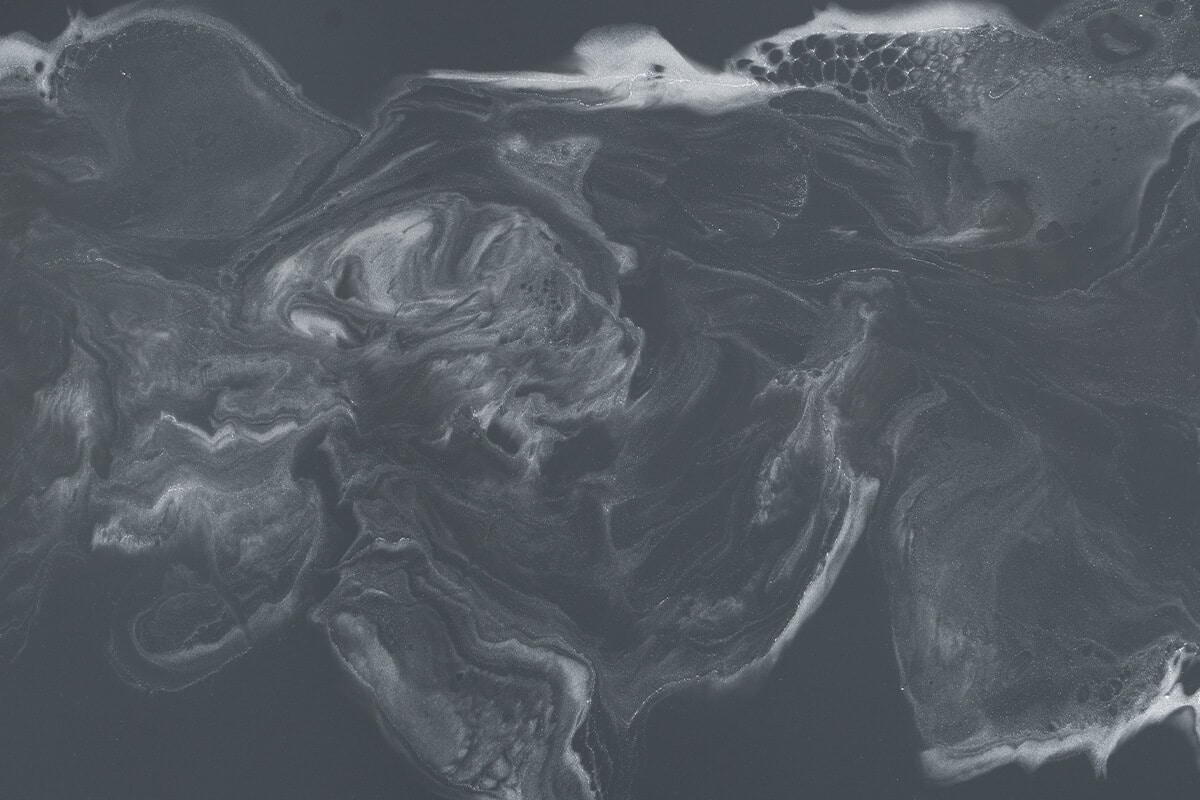

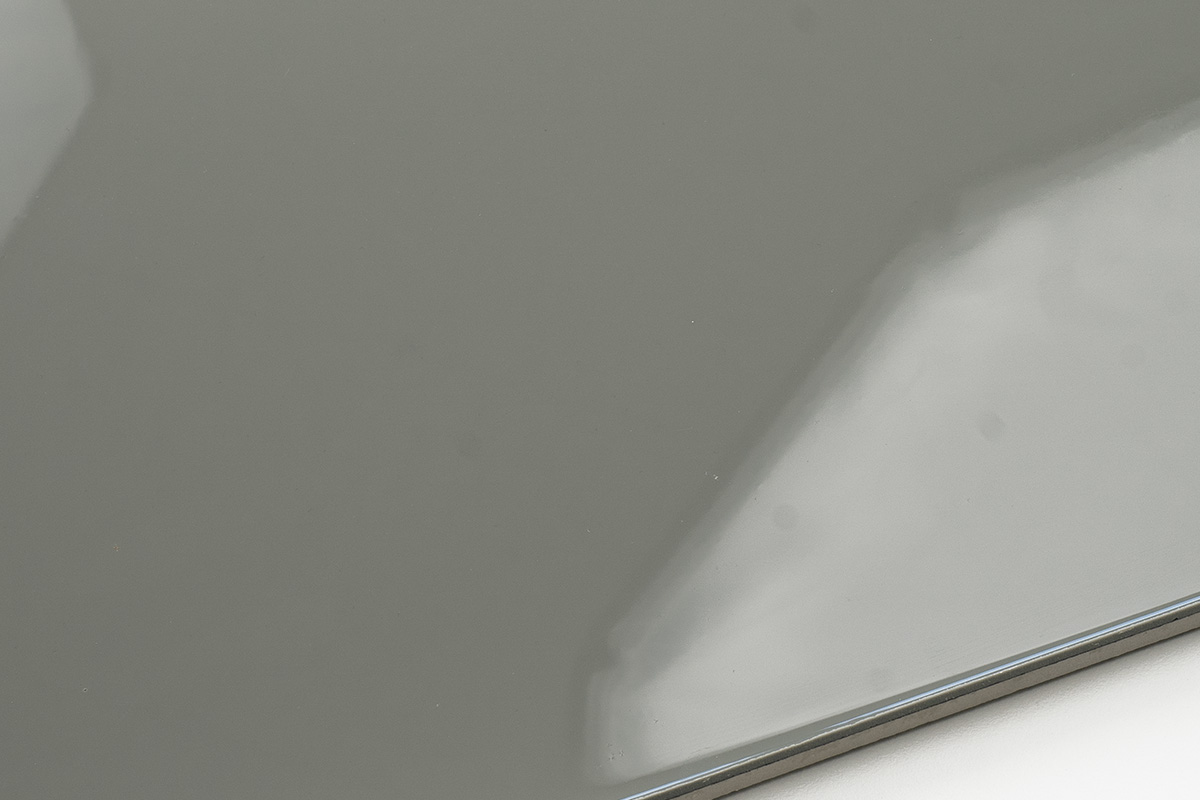

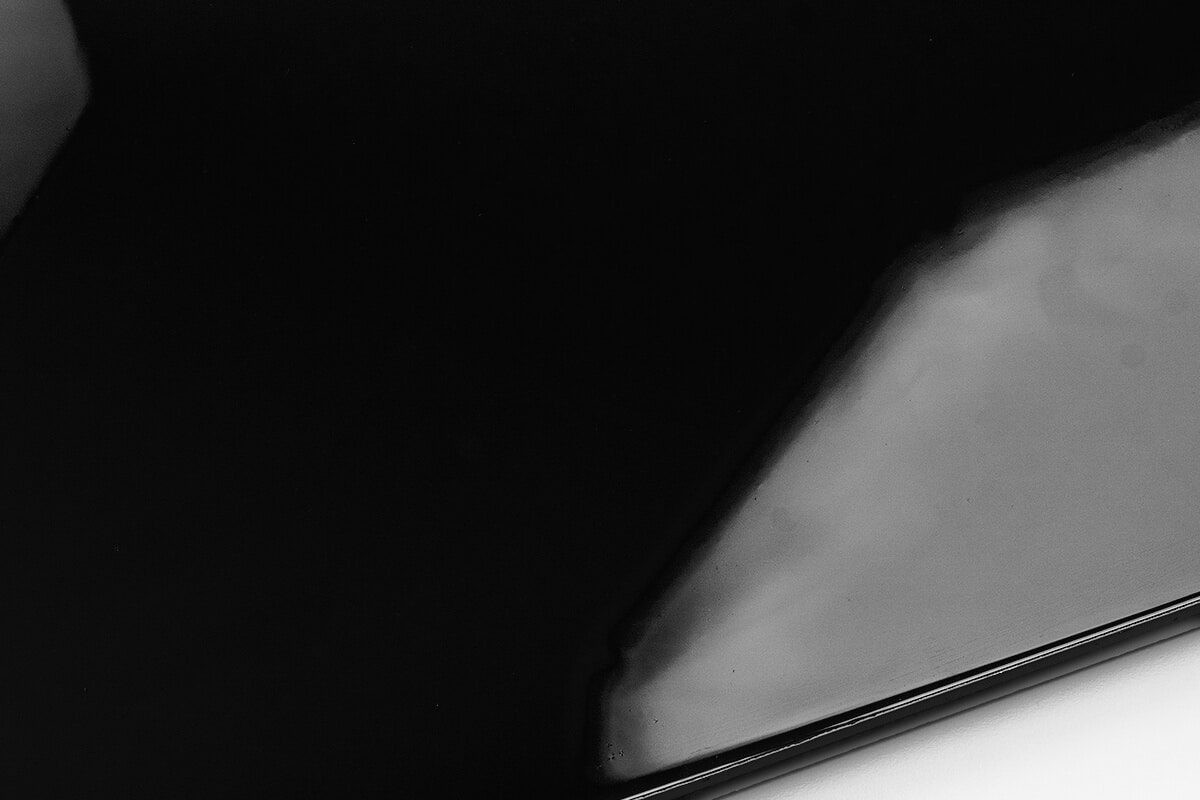

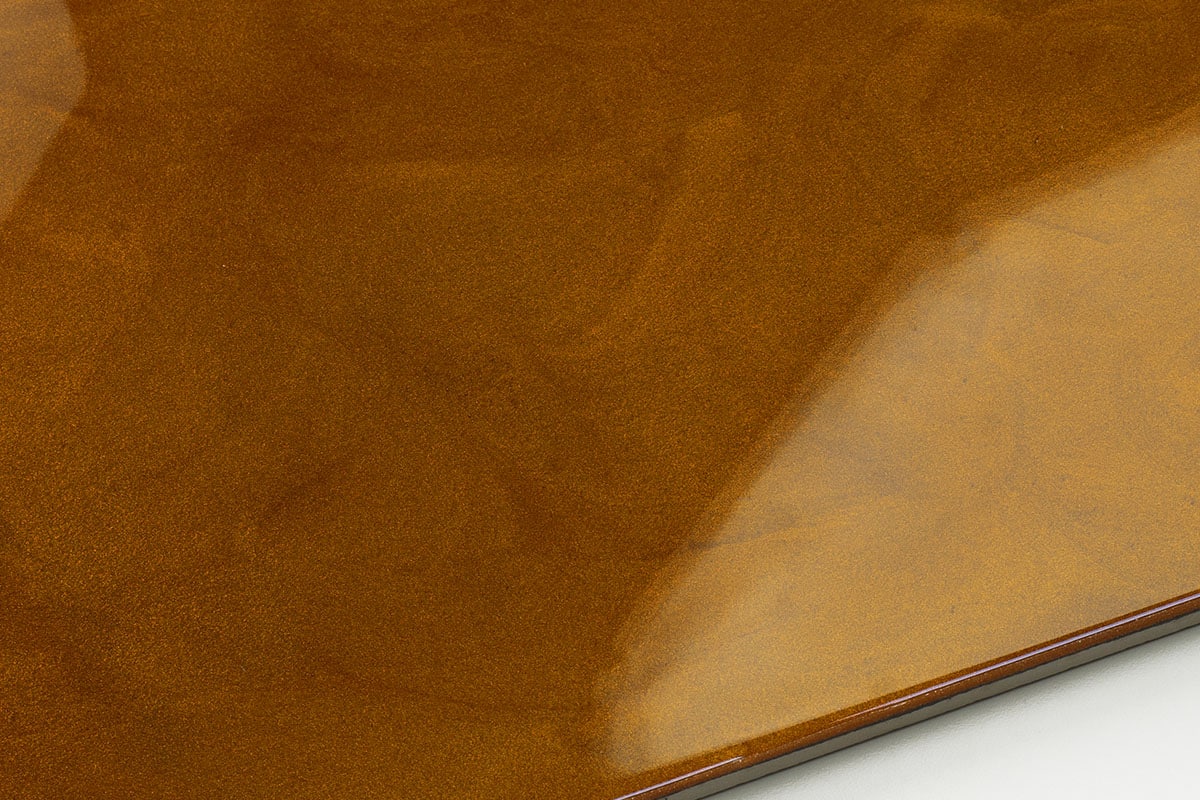

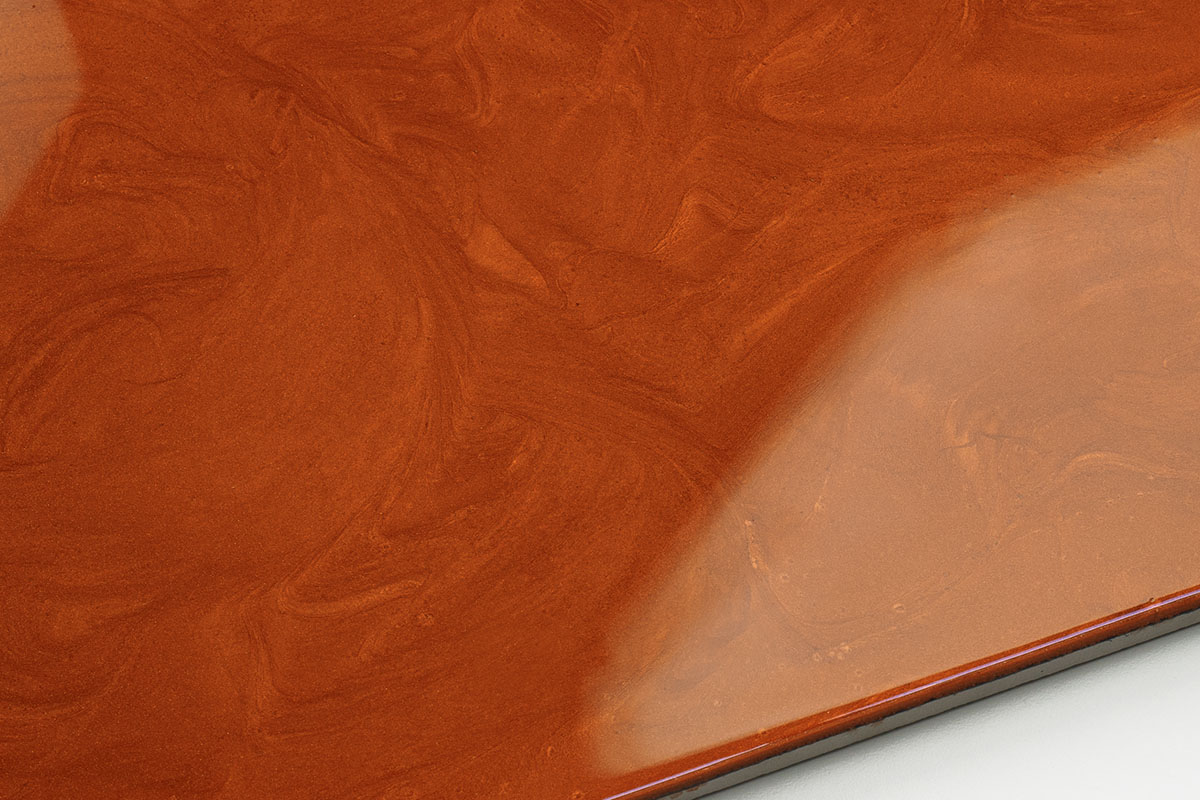

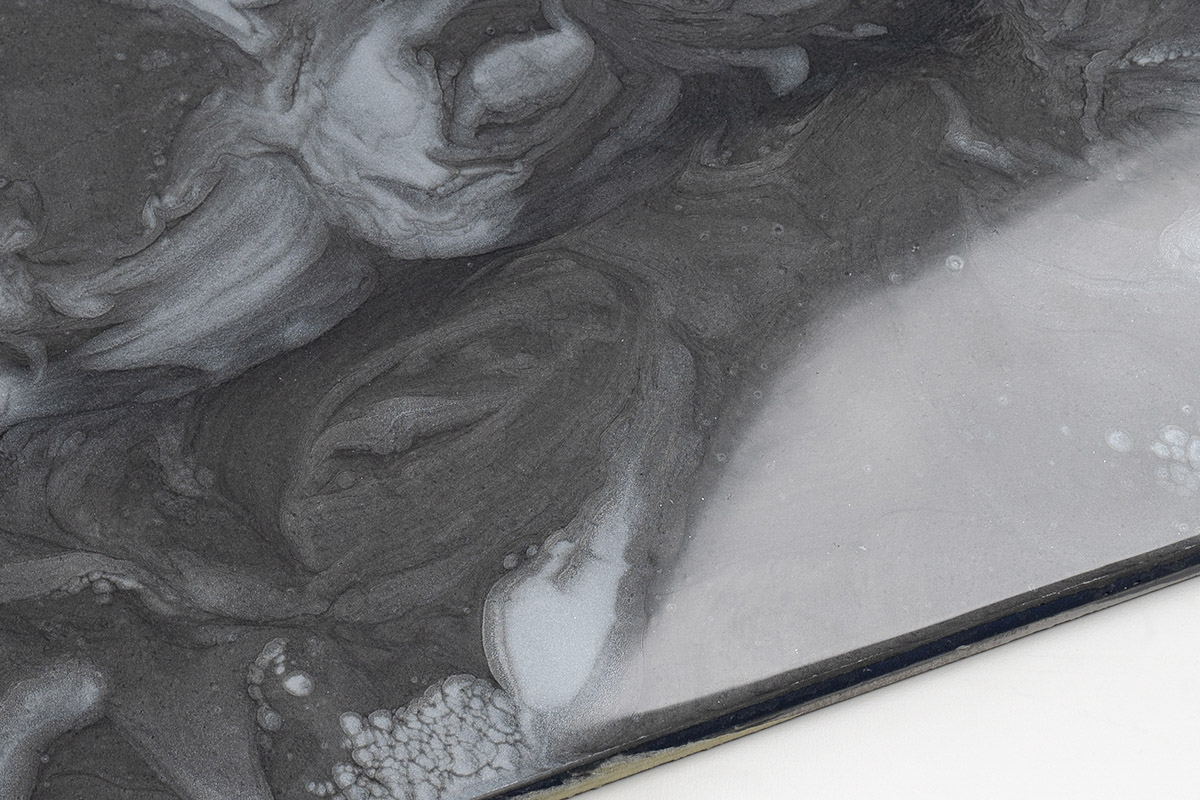

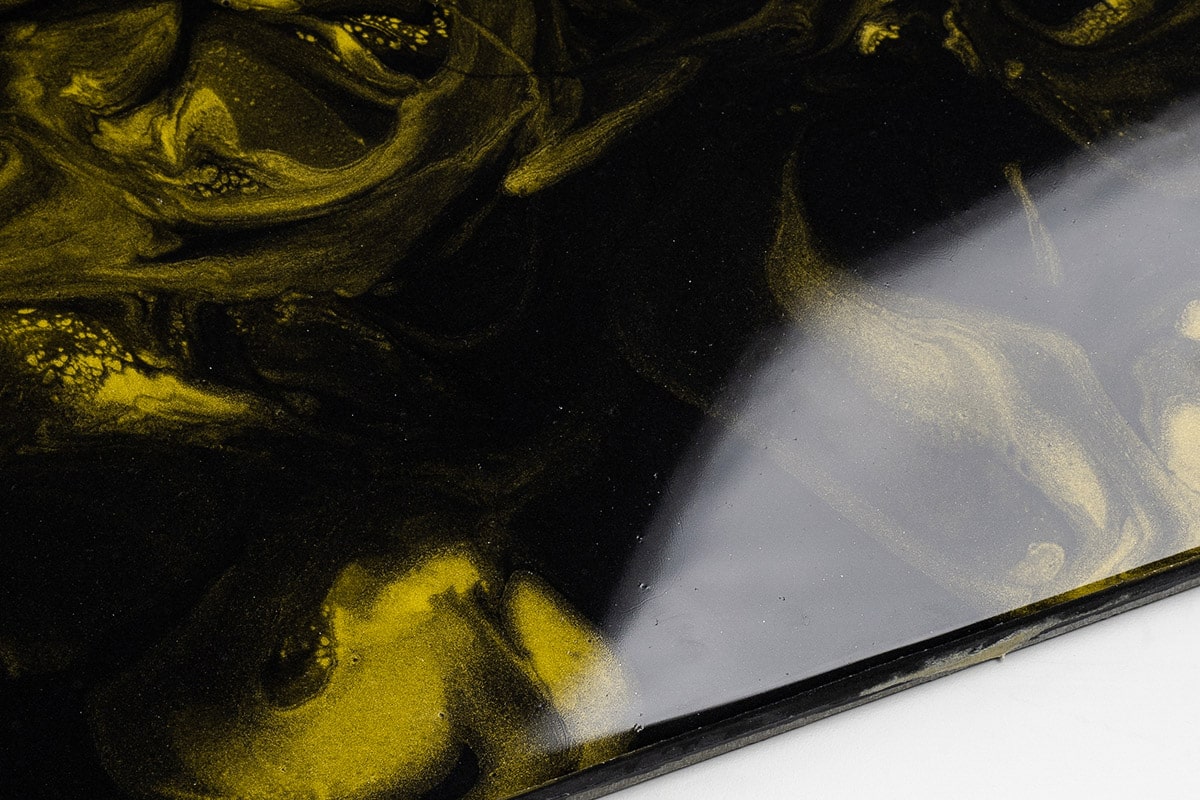

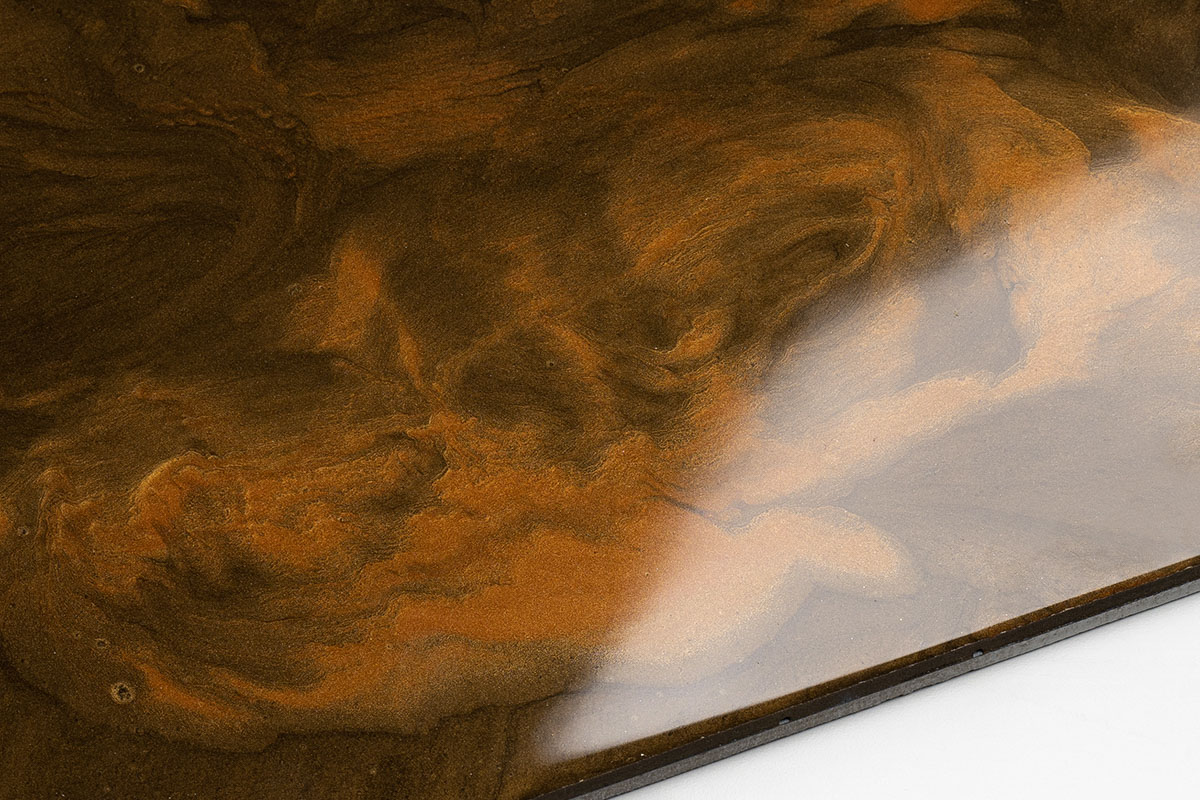

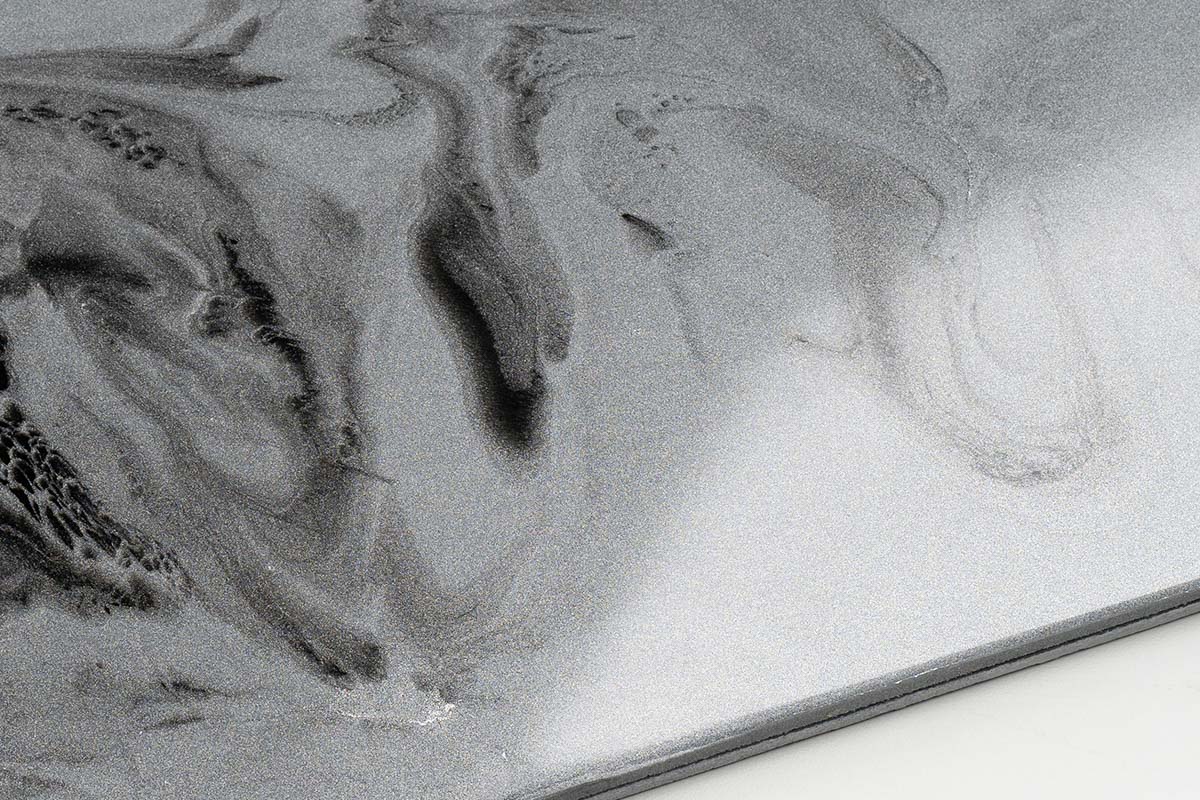

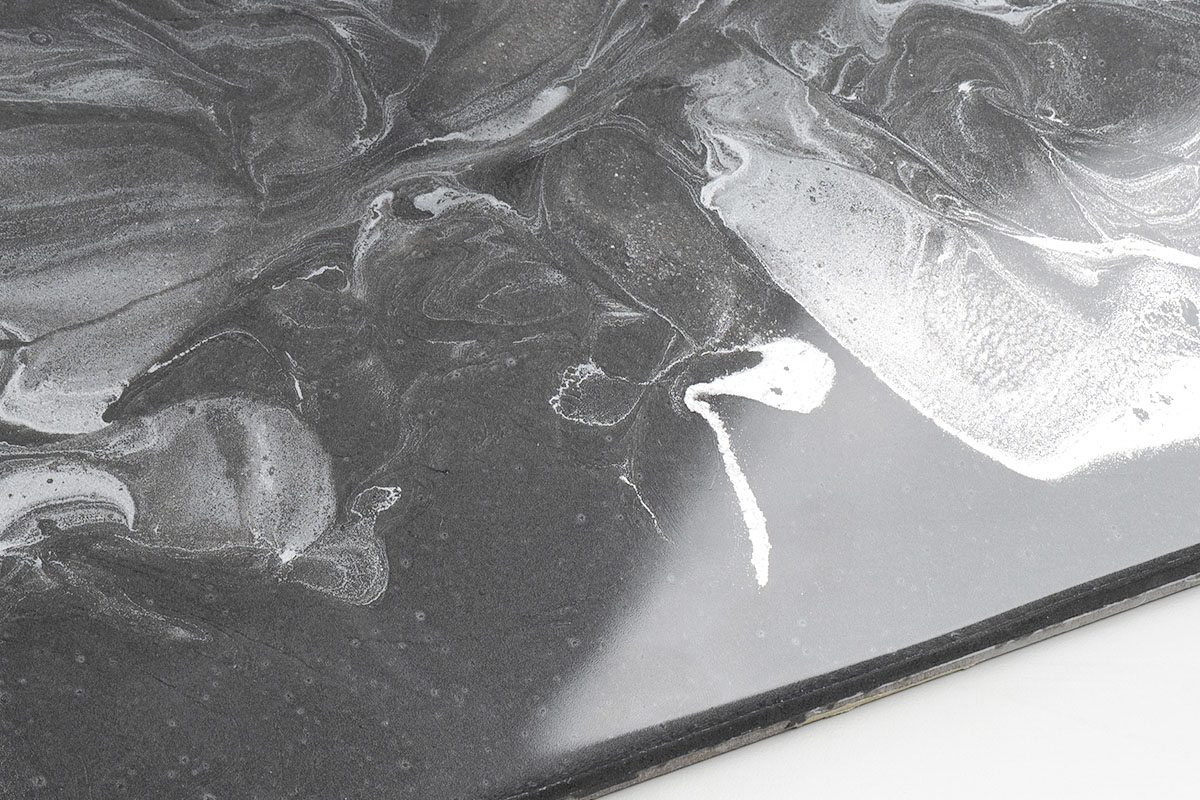

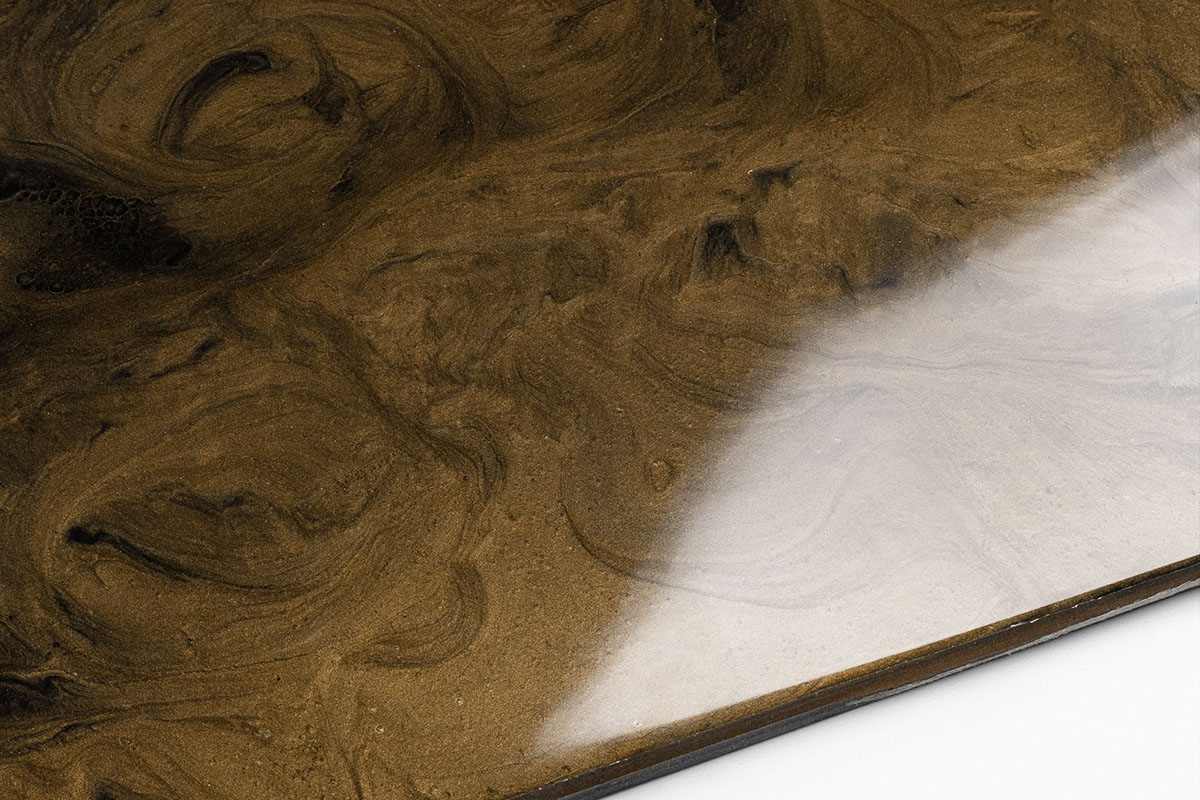

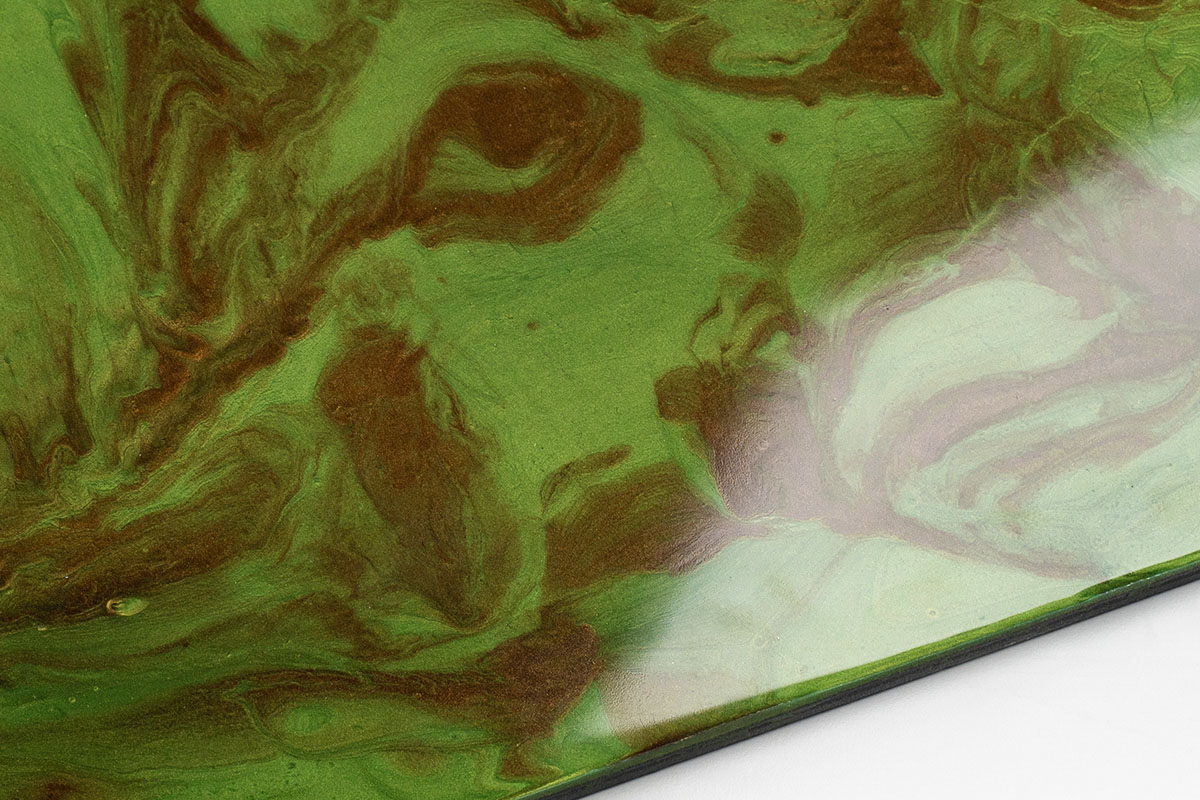

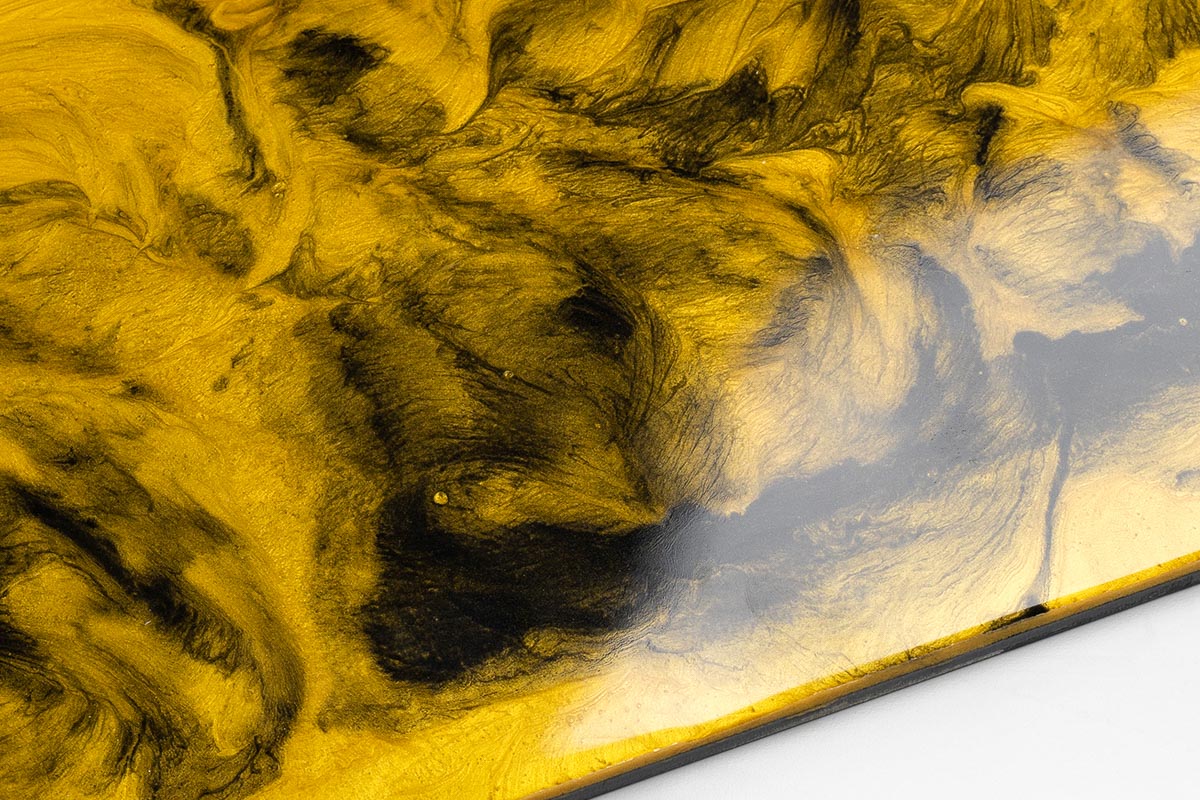

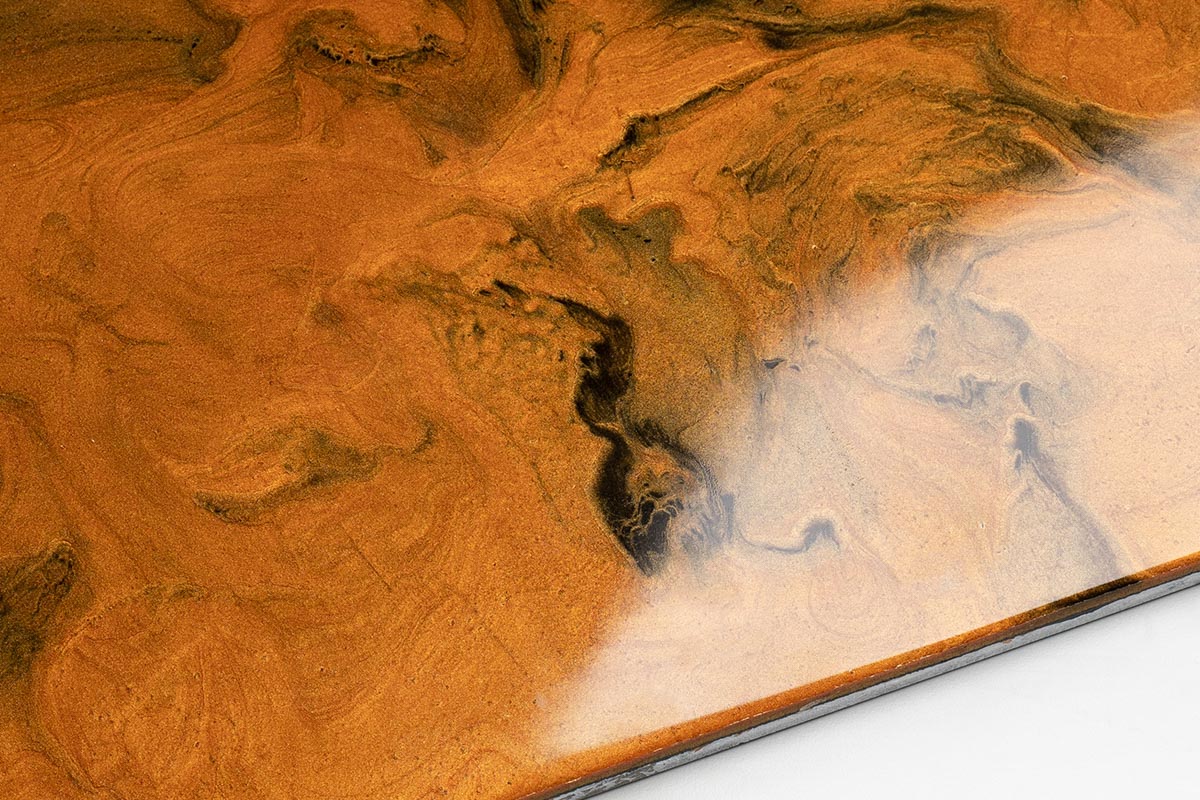

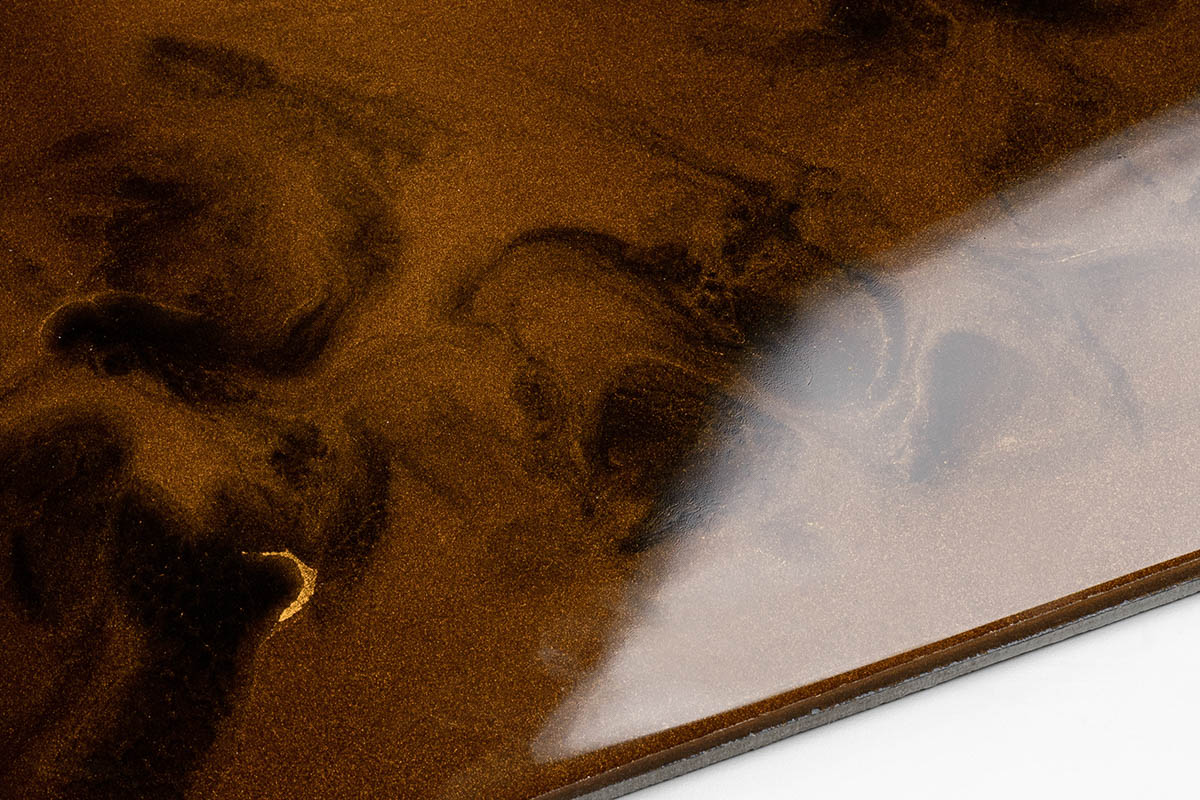

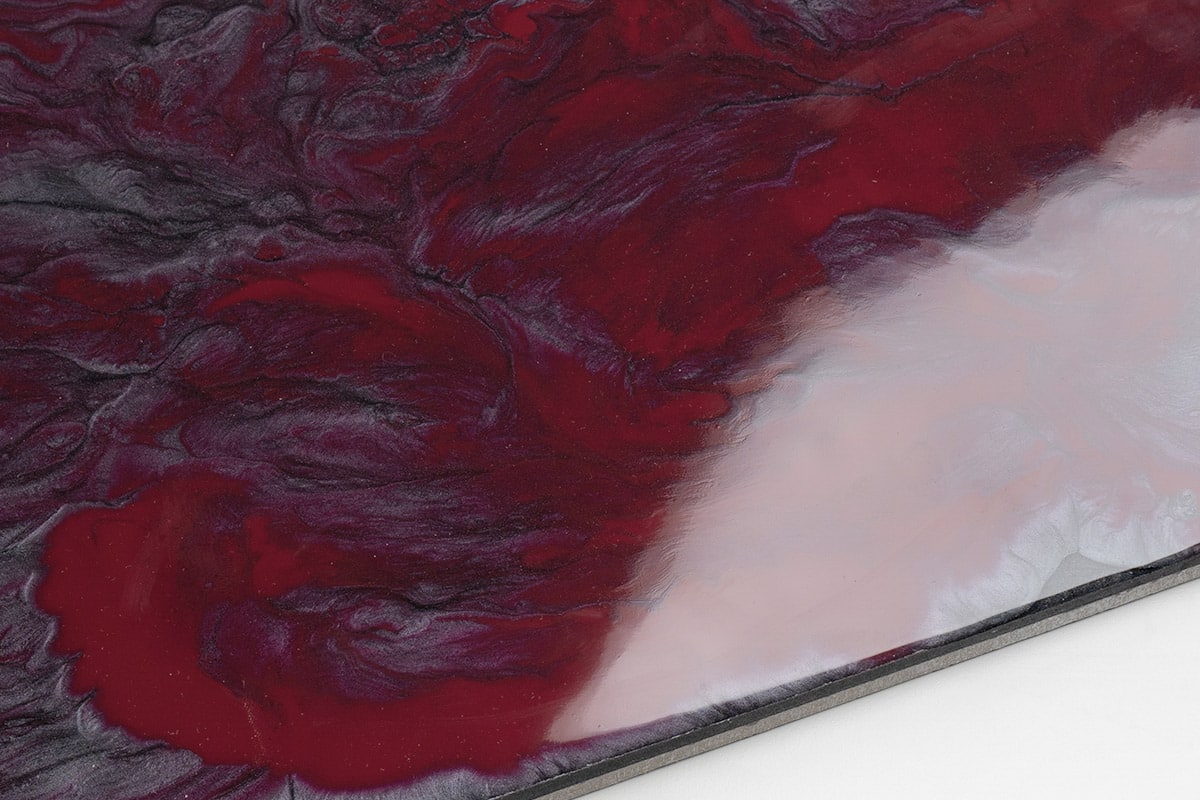

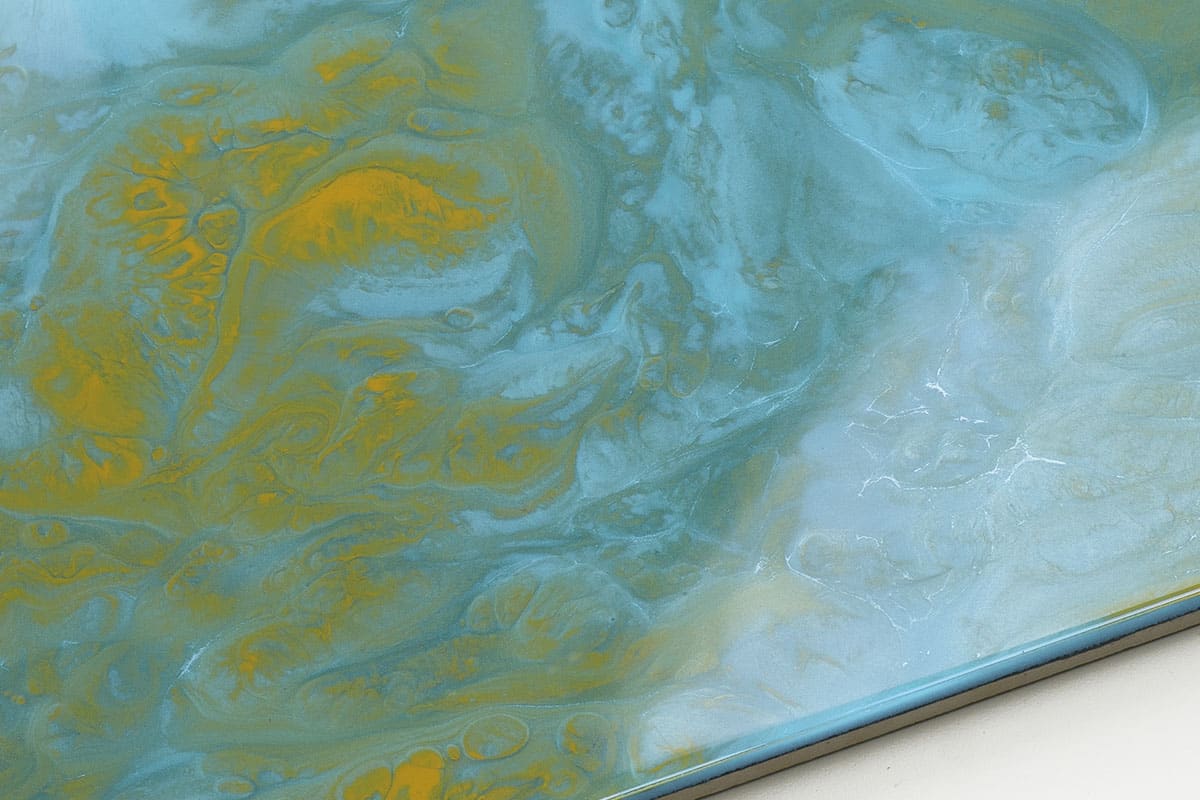

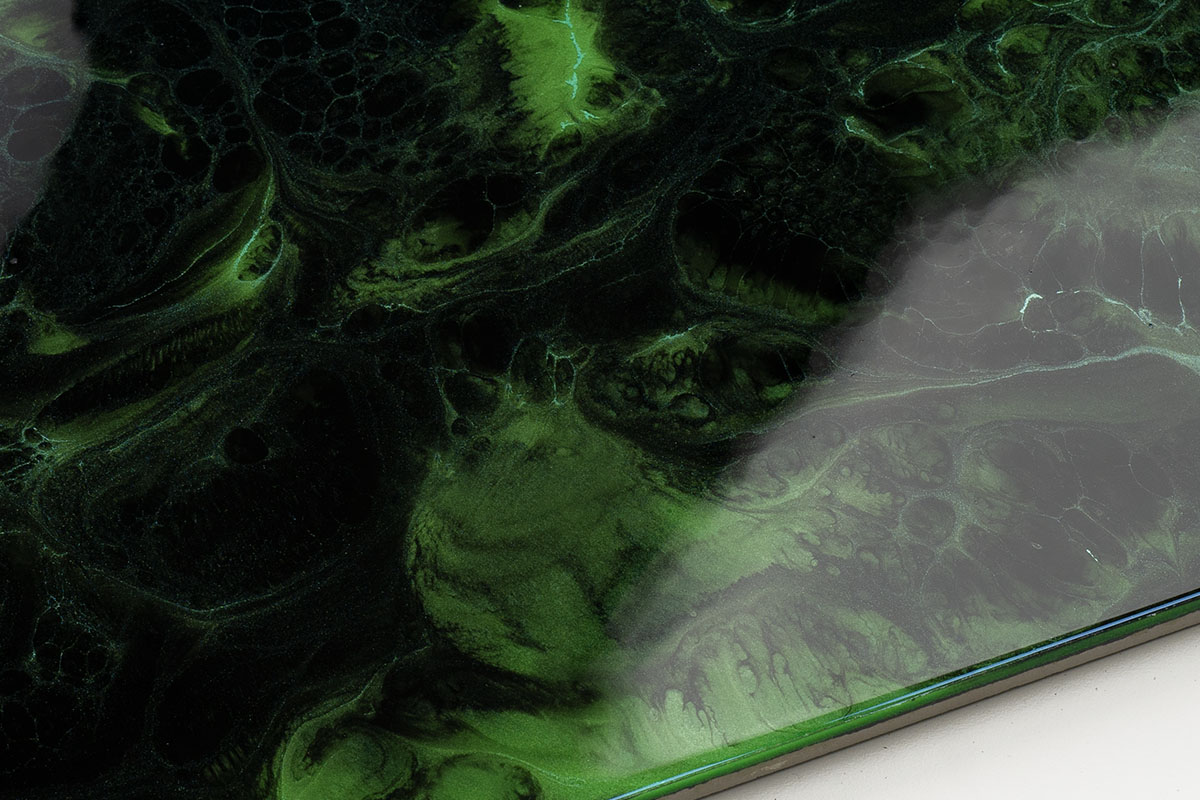

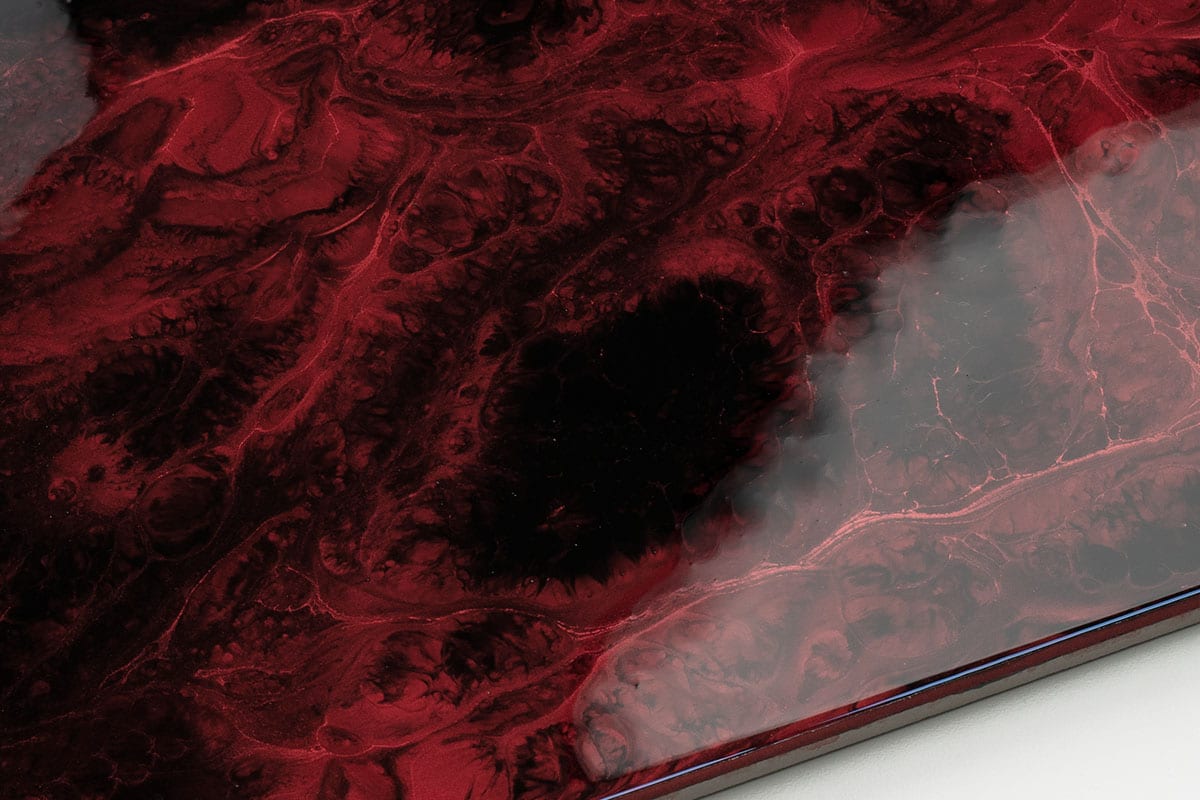

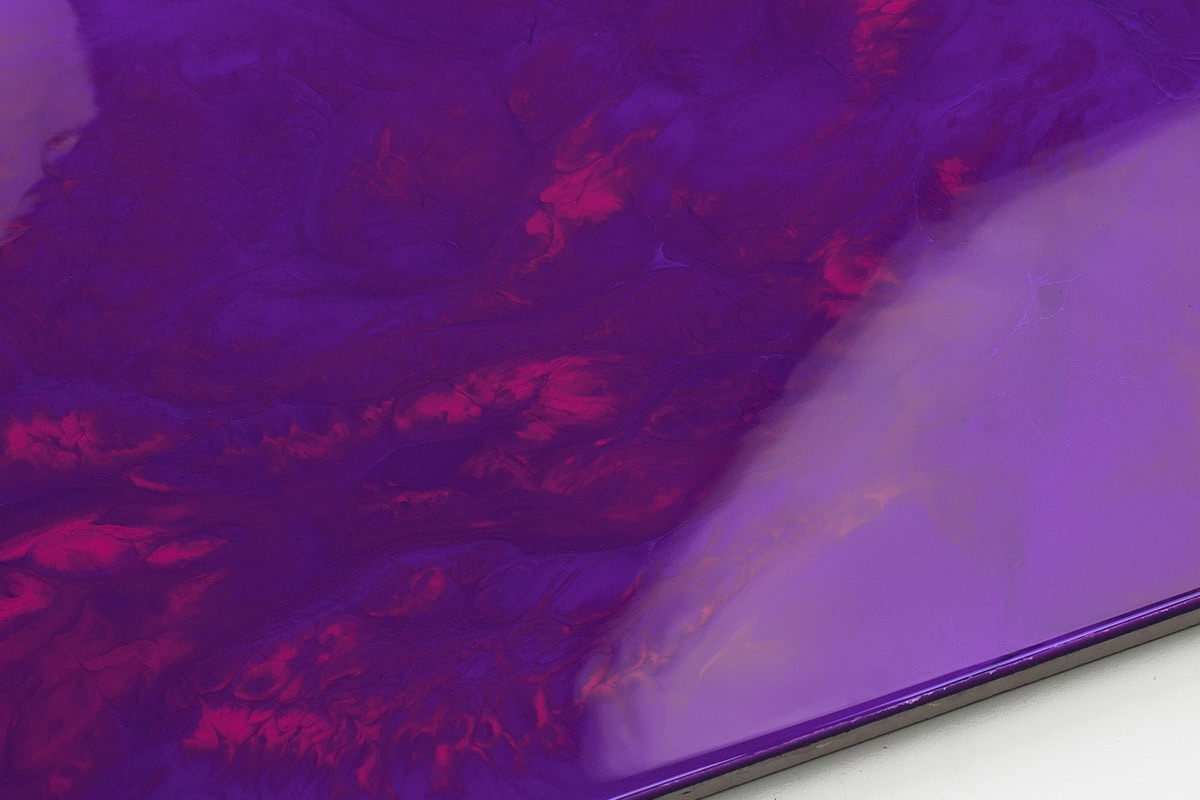

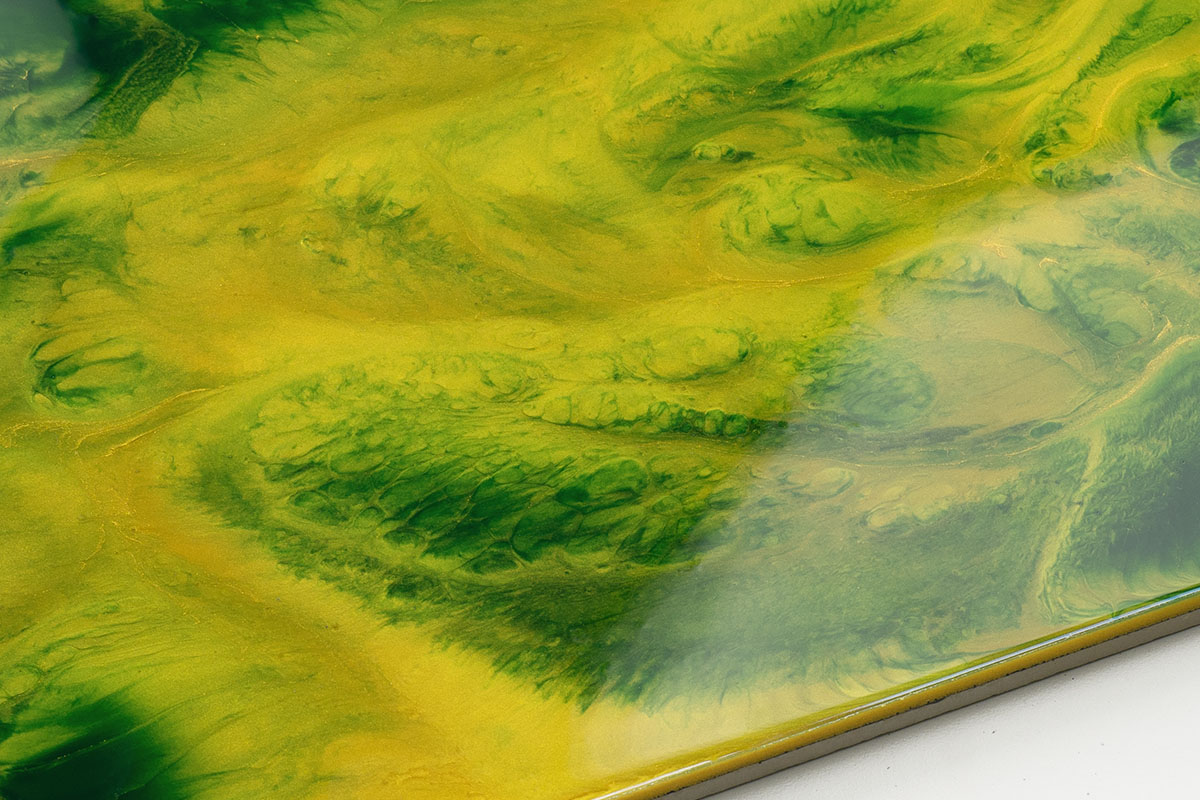

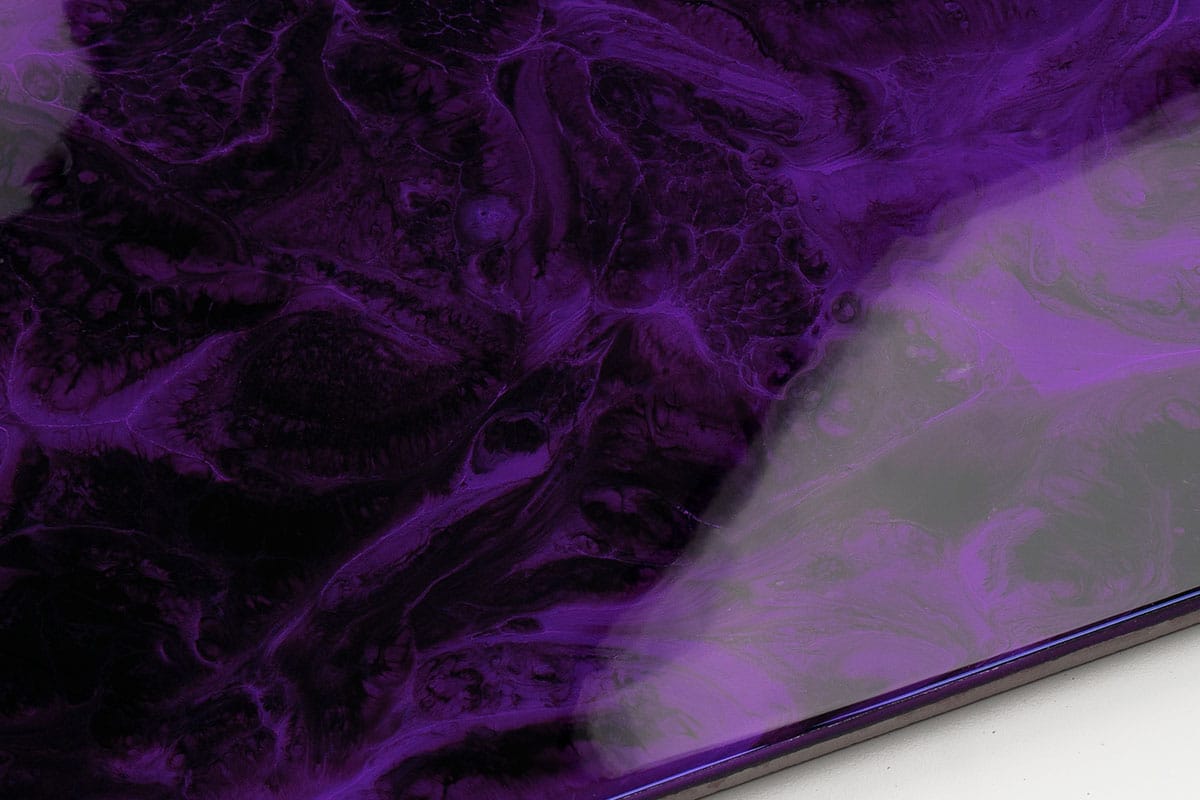

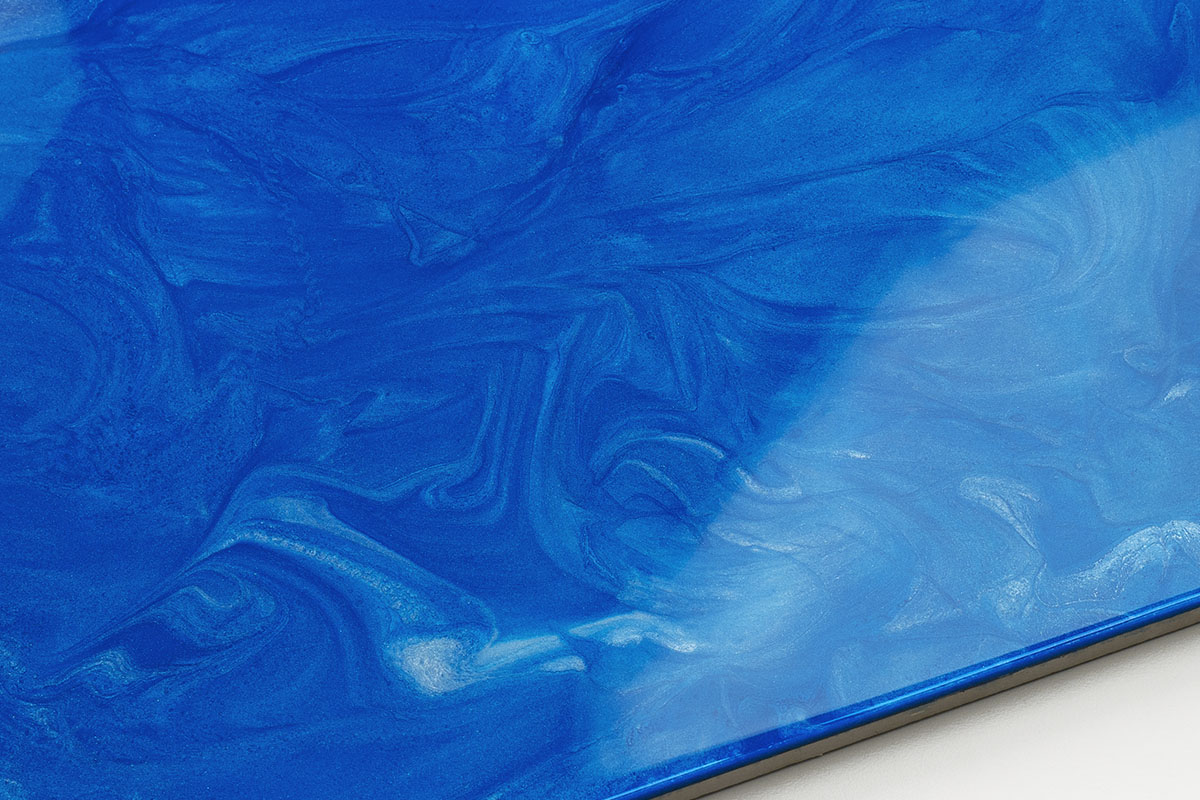

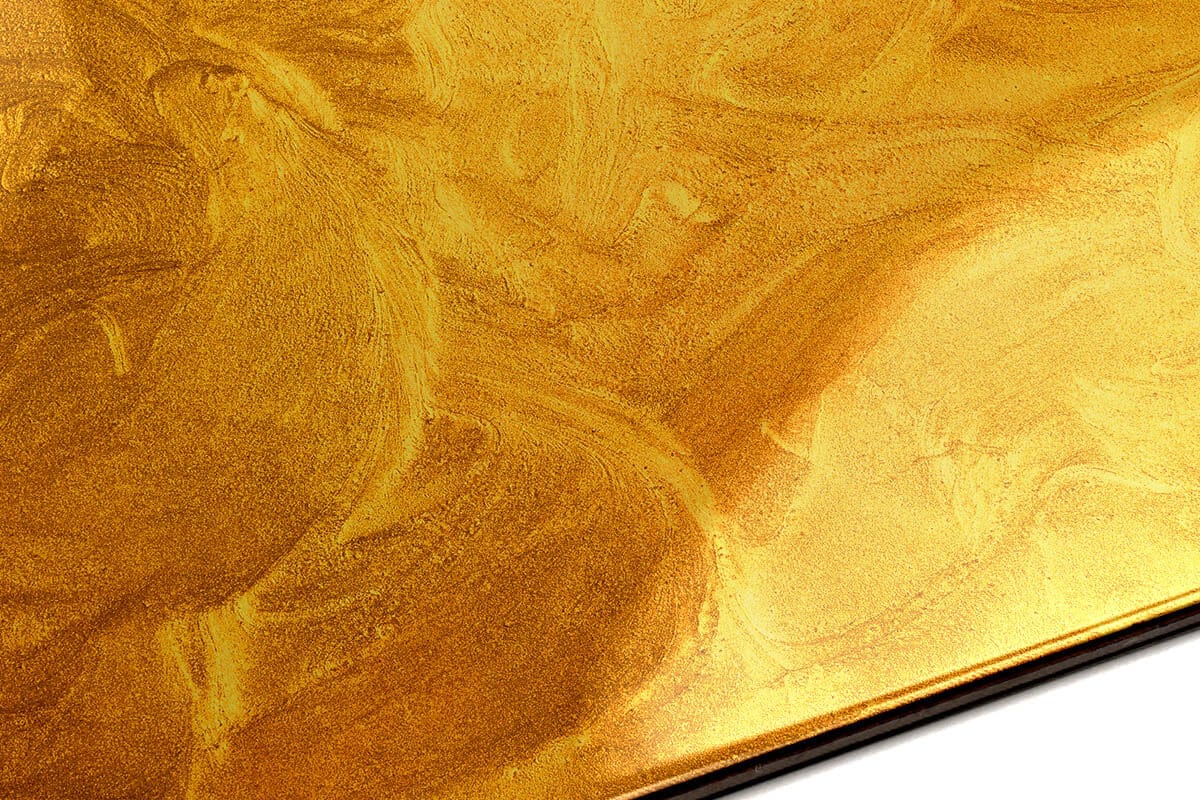

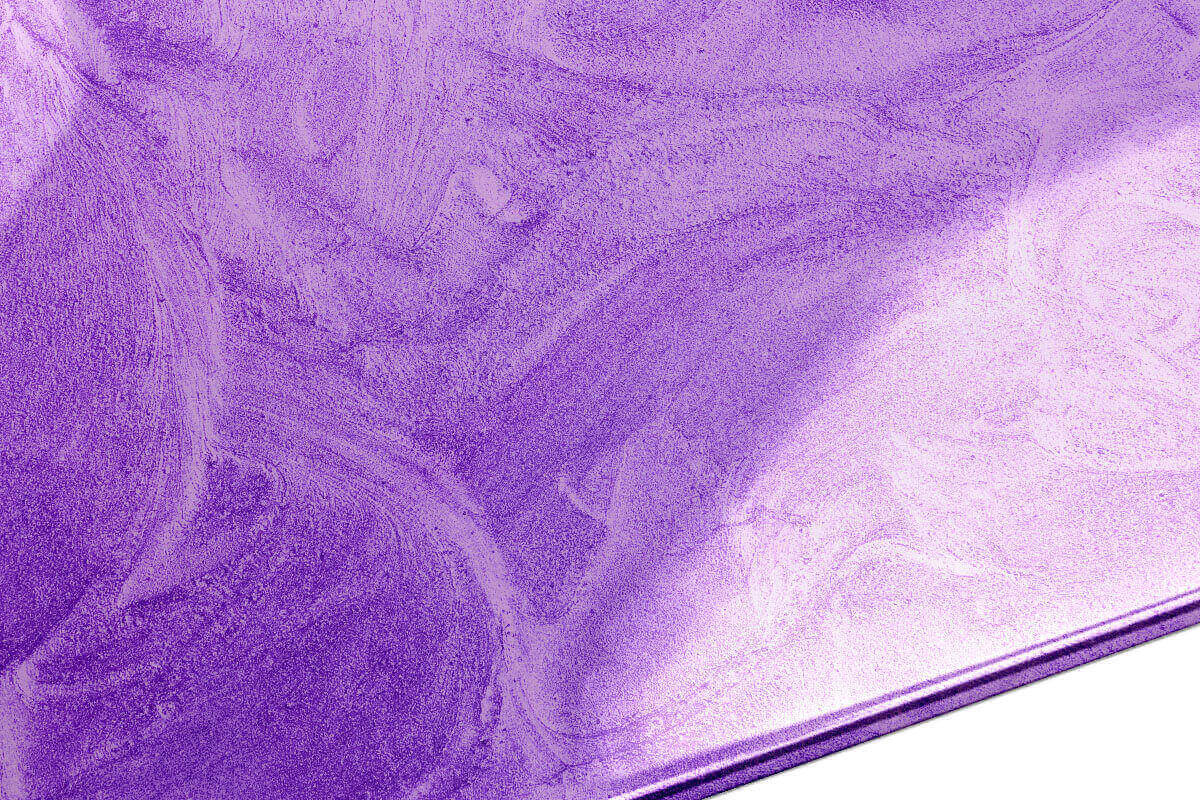

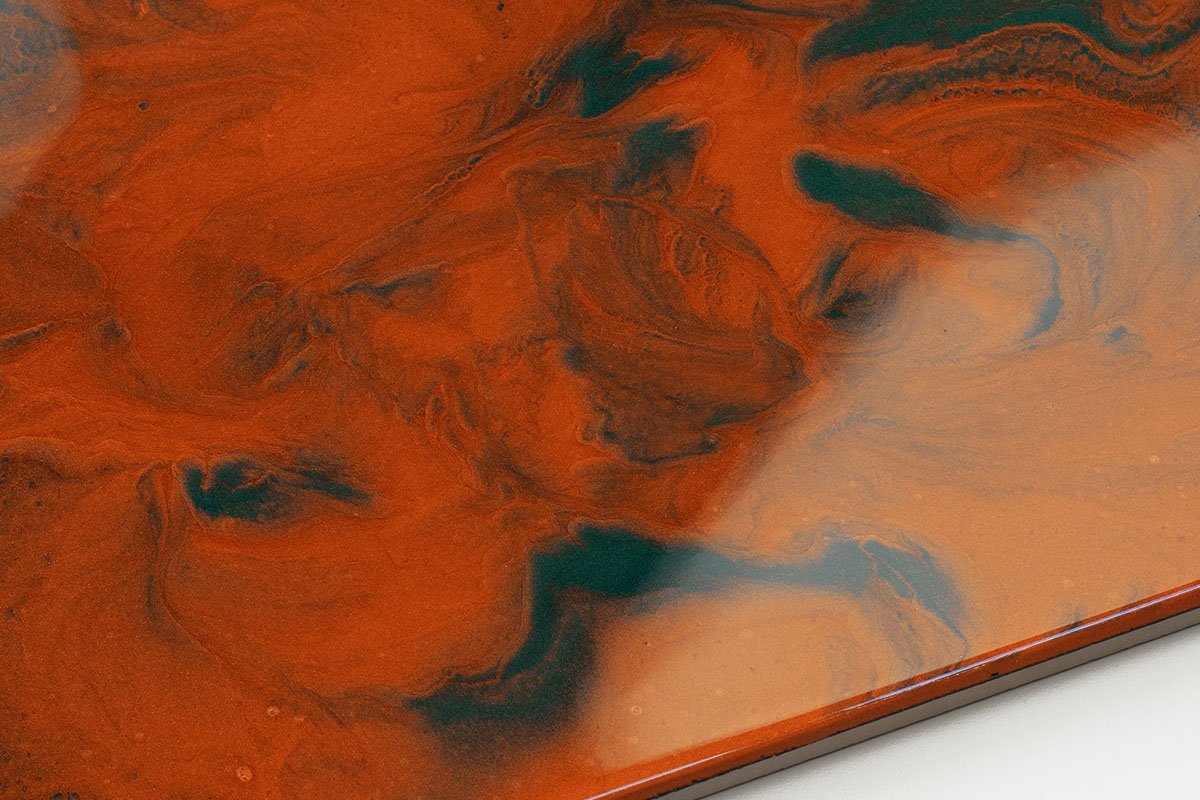

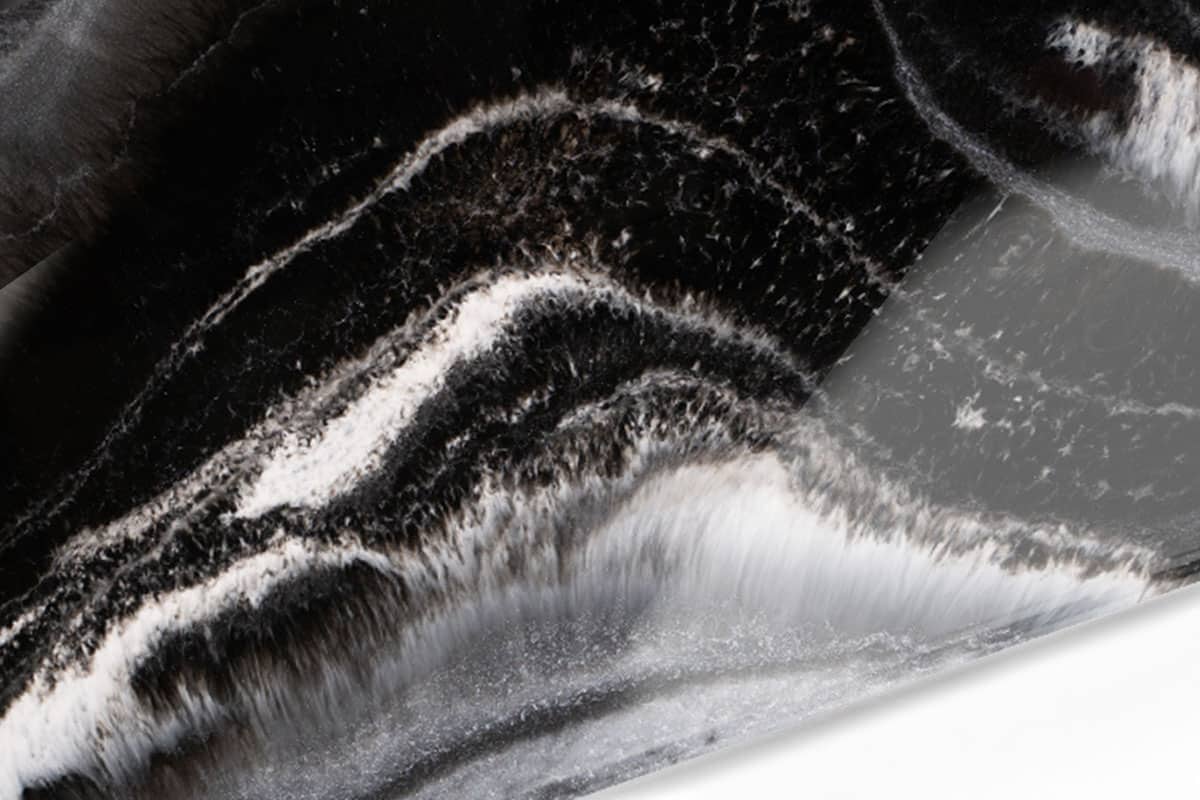

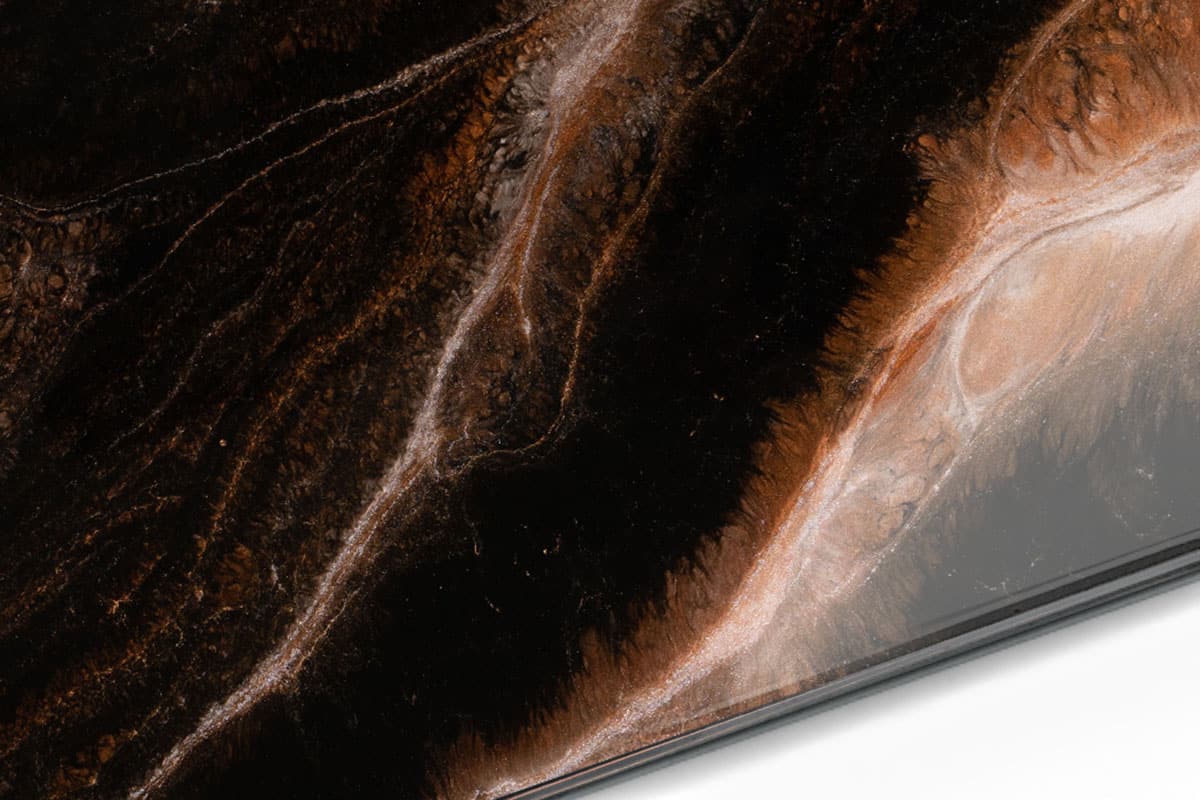

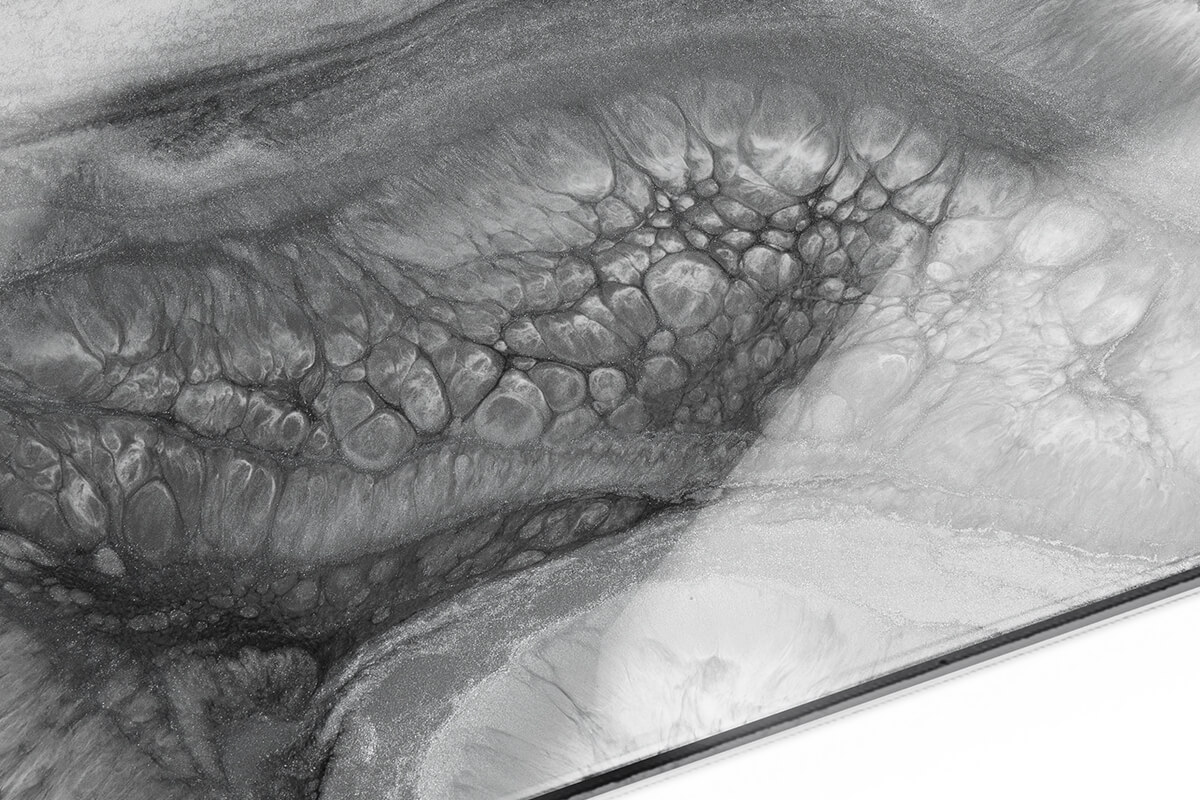

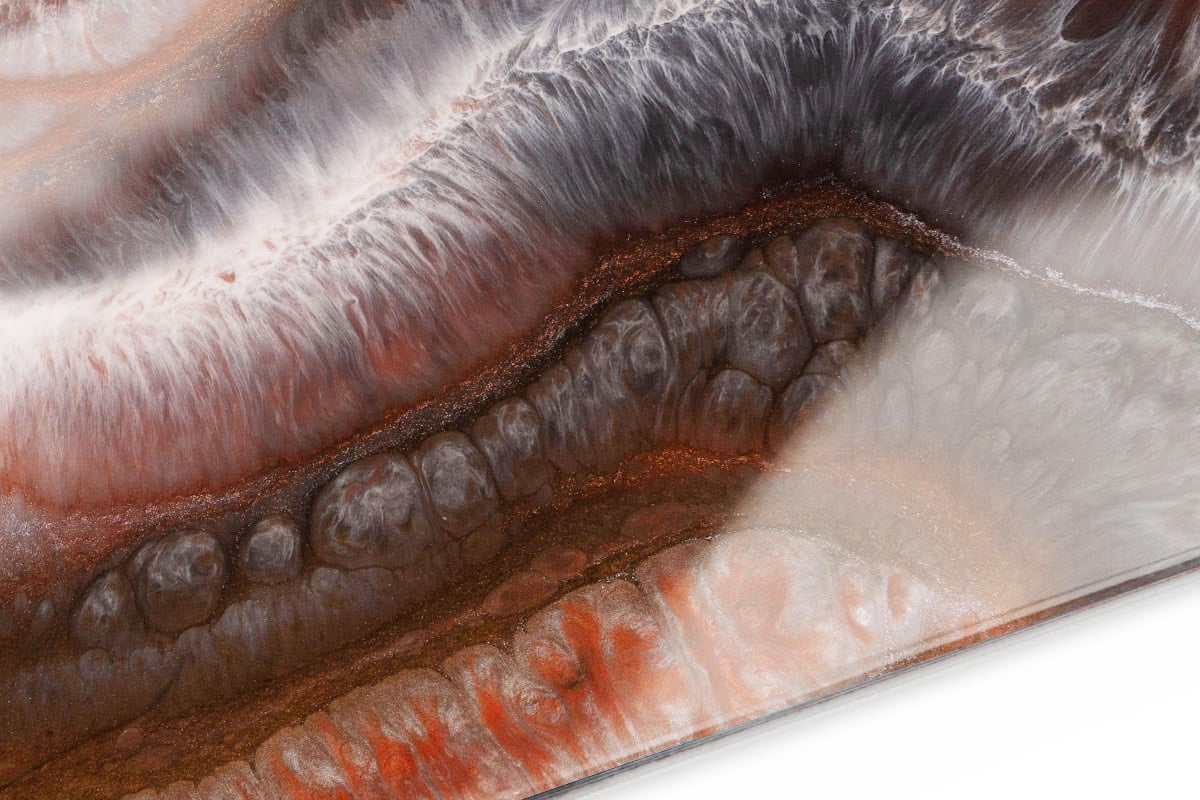

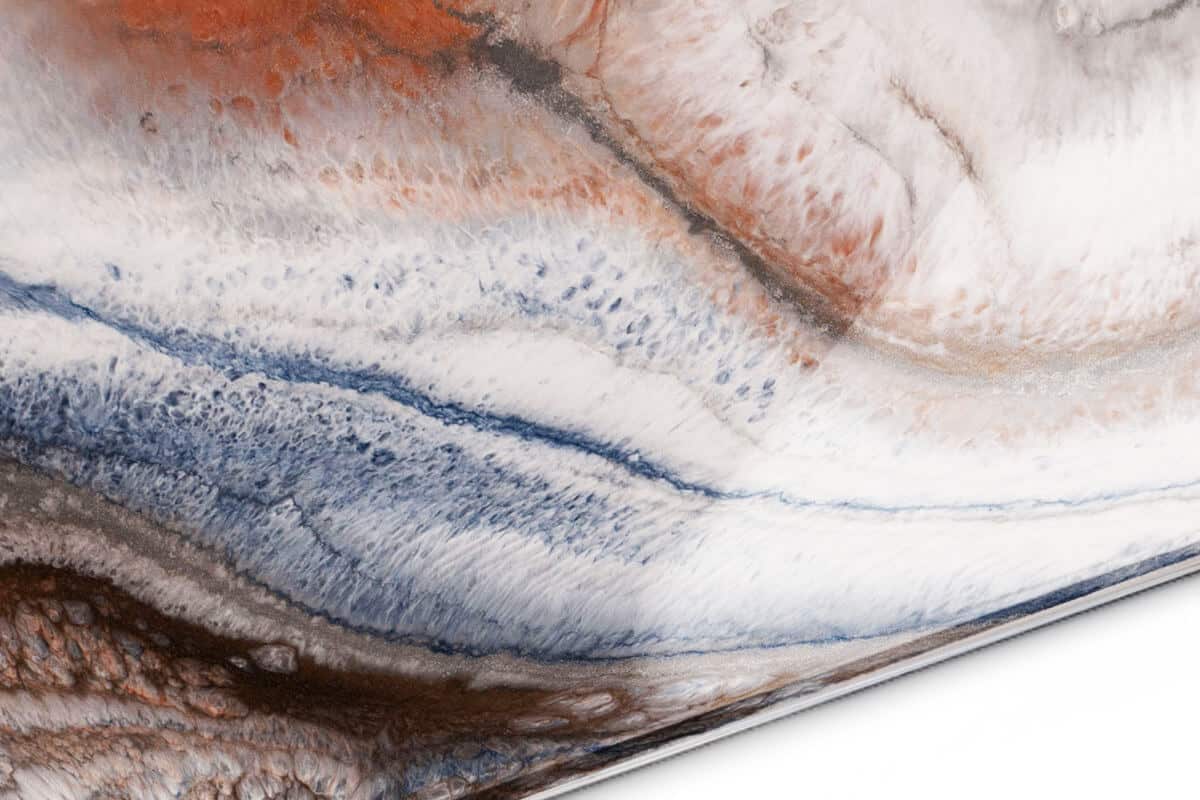

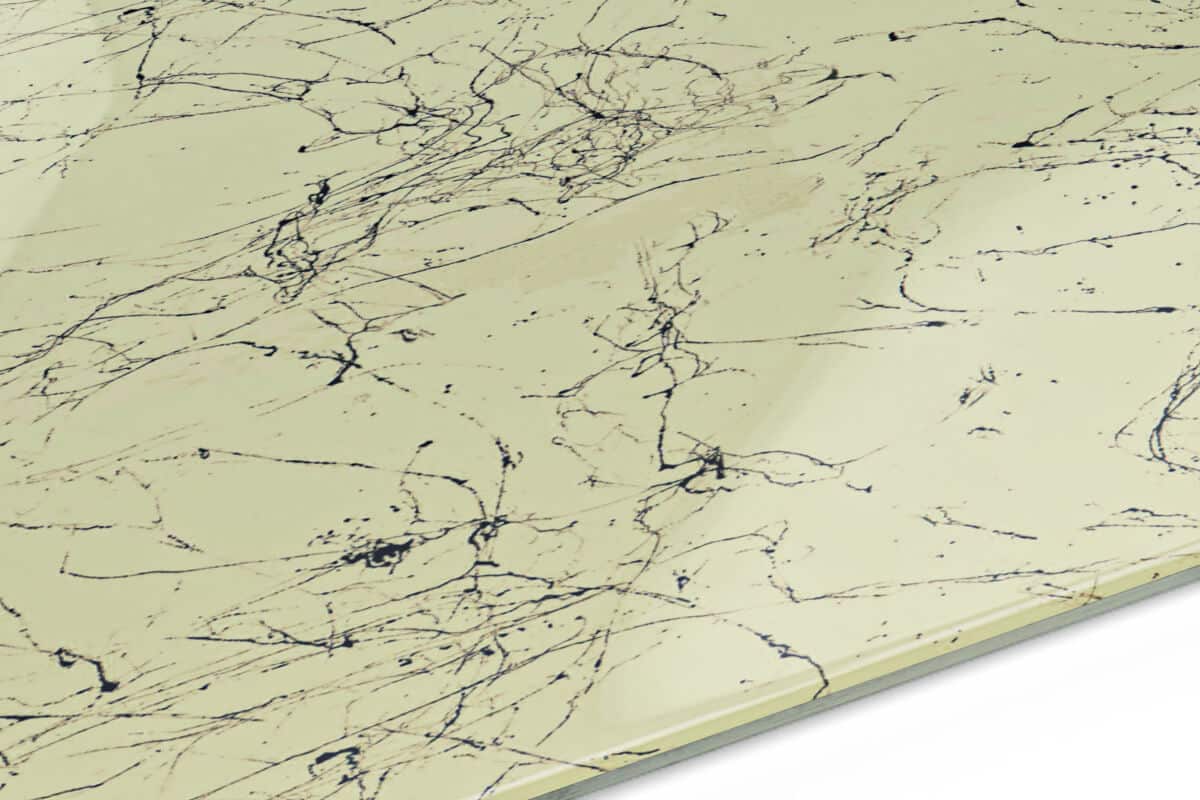

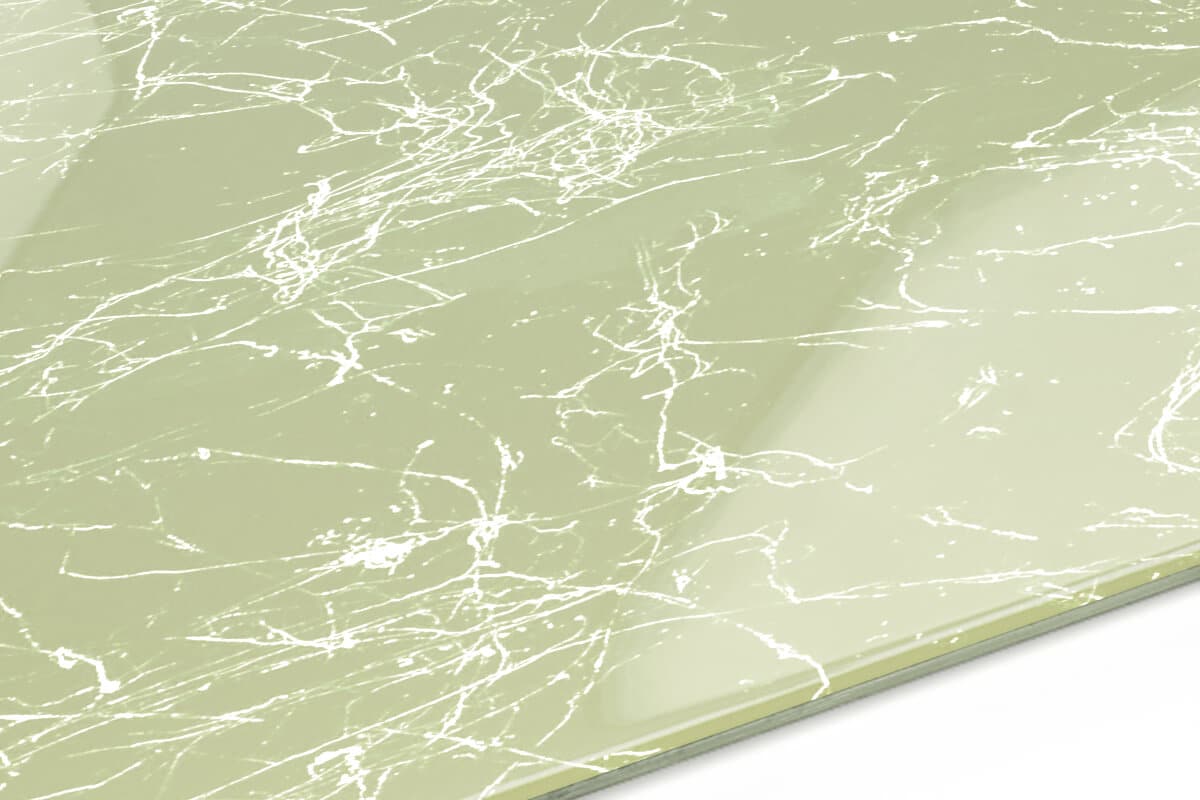

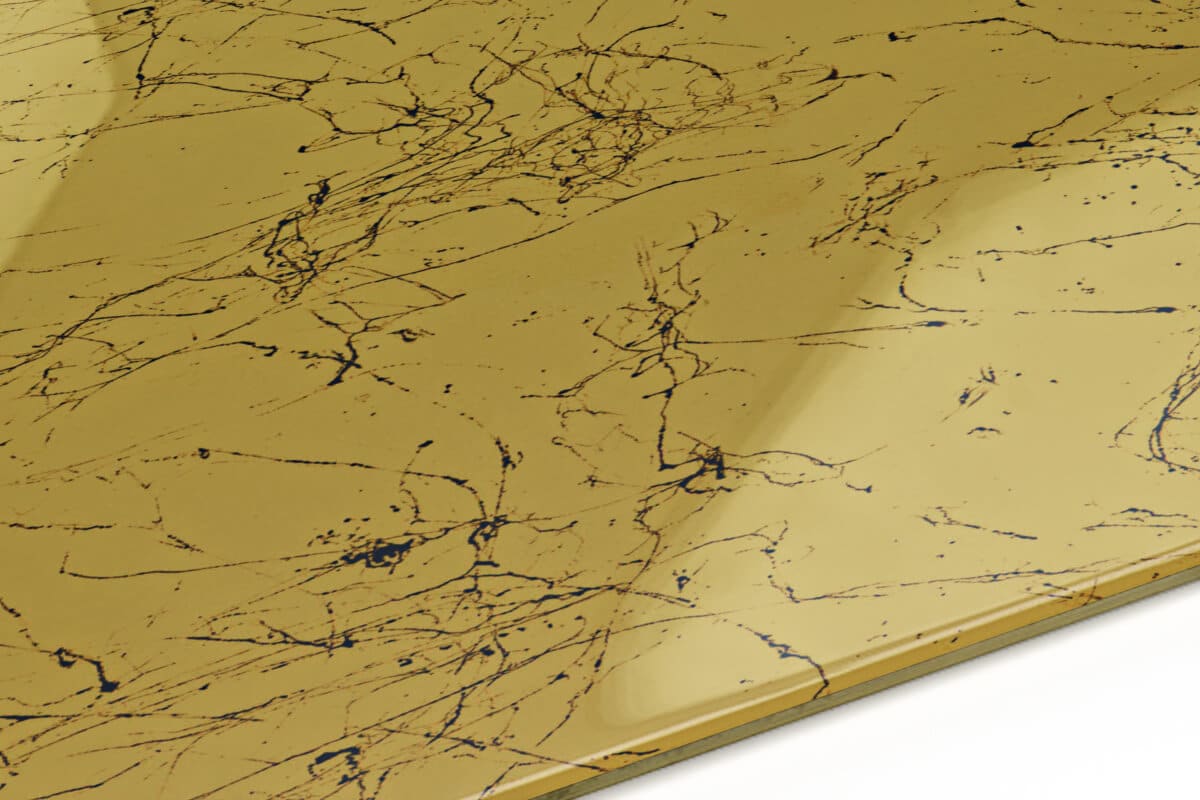

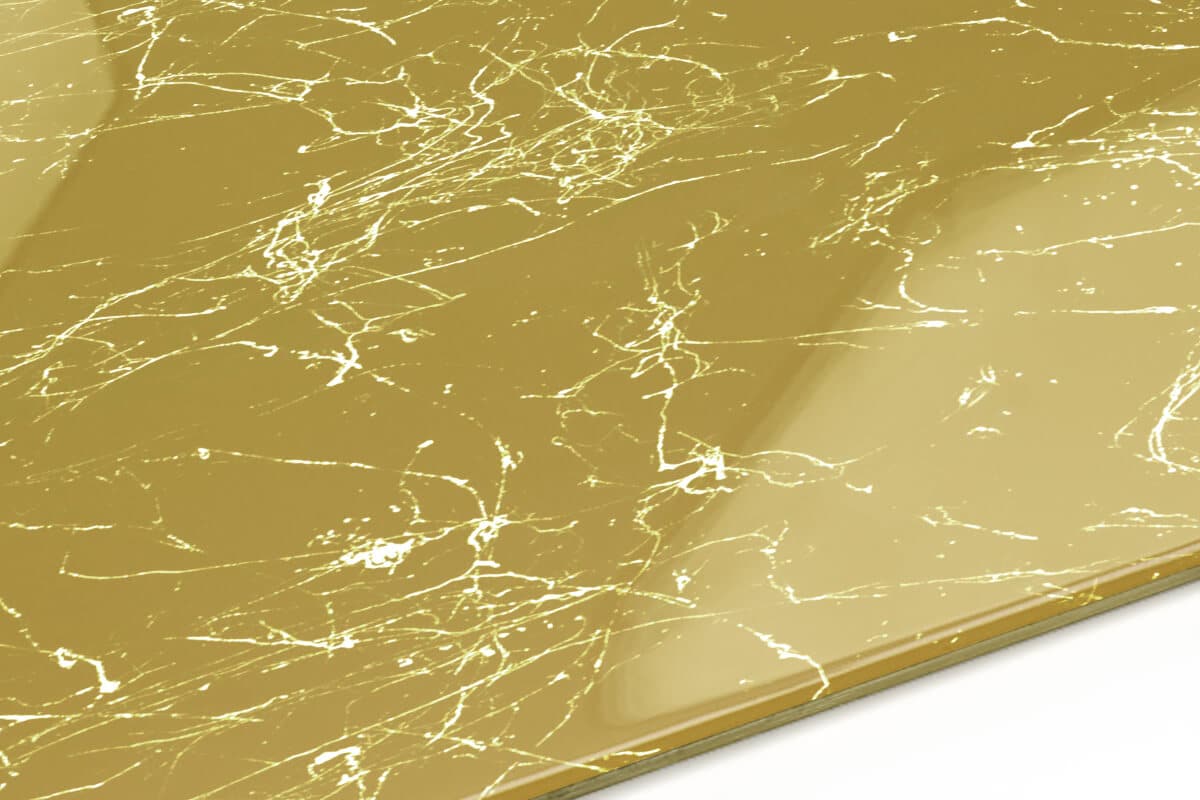

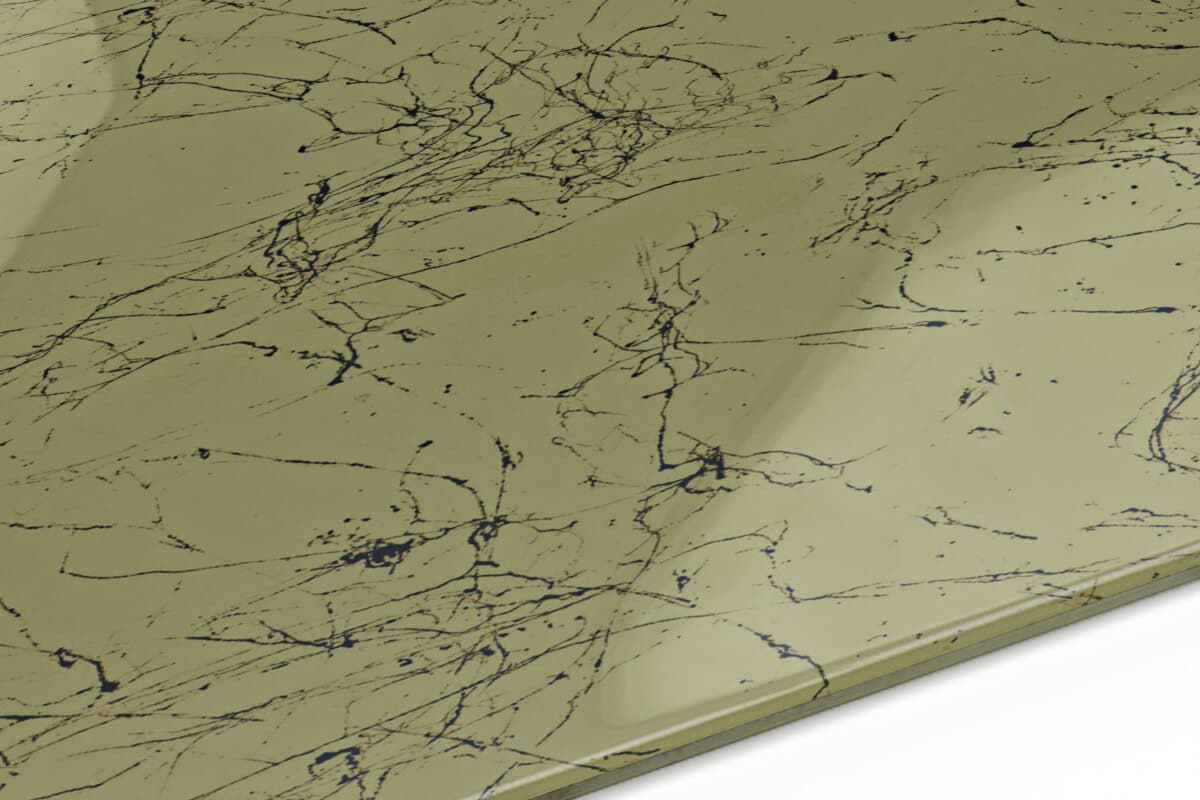

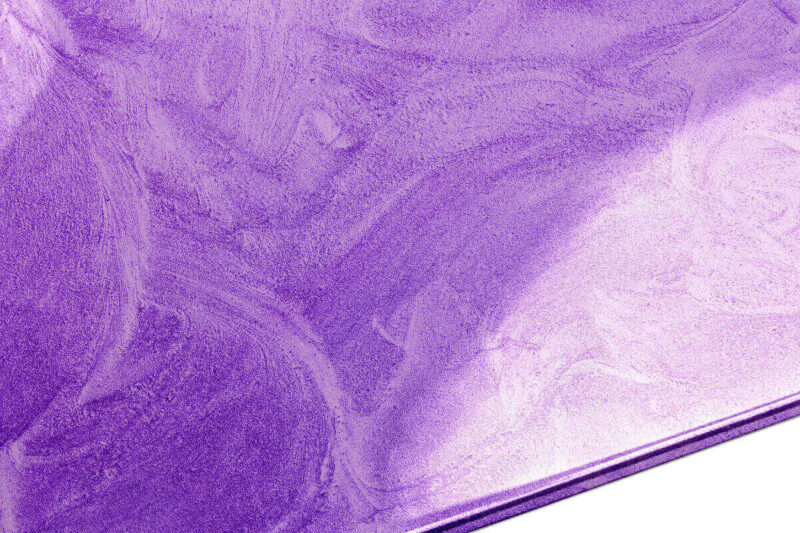

✓ No surprises. You always get the color you see online. We present all our colors in 4K videos and high-resolution pictures so you can see exactly what you are getting.

✓ Professional easy to follow step-by-step tutorials.

✓ Money-Back Guarantee

✓ Same Day Shipping

✓ Delivery across USA

✓ Friendly 24h-Support

Get the products you’ve always dreamed of!

✓ The biggest color selection on the market.

✓ The best epoxy properties across the USA:

- Bubble Free

- Odorless

- Solvent Free

- BPA Free

- Easy to Use

Instructions for Primer

- We recommend a working temperature of approx. 70°F.

- The surface should be dust-free, clean, and even. Level out holes, unevenness, and slopes in advance with leveling compound.

- Always start with our EPOXY PRIMER. Stir the primer with a stir stick.

- Pour the material into a paint tray after mixing.

- Roll the material onto the desired surface with a paint roller.

- Allow the primer to dry (approx. 8-12 hours).

Instructions for Main Coat

- Plan a quantity of resin and hardener for each colour. We recommend to use 90% of your resin and hardener for the base color IRON GRAY, and 10% for the highlight color PEARL WHITE.

- First, prepare a mixture for the base color IRON GRAY.

- Mix the resin (A) with the hardener (B) in a ratio of 2:1 (e.g., 2gal resin + 1gal hardener).

- Ideally, transfer the material to a clean mixing bucket and stir again. This will ensure that the resin (A) and hardener (B) are completely mixed together.

- Add the supplied color paste IRON GRAY to the the resin-hardener mixture.

- Pour the material onto the surface immediately after mixing, as the product can boil up in the mixing bucket.

- Apply the material with a squeegee and foam roller flooding the entire surface.

- Now mix the highlight color PEARL WHITE.

- Mix the resin (A) with the hardener (B) in a ratio of 2:1 (e.g., 2gal resin + 1gal hardener).

- Add the supplied PEARL WHITE metallic powder to the resin/hardener mixture.

- Work the color into the base color wet in wet as a highlight.

- The main coating is cured after 16-24h.

Info: Epoxy resin is sensitive to any kind of moisture during curing (risk of amine blush formation, i.e. white patches in the top layer). For this reason, we recommend that you avoid any contact between water and the epoxy until it has cured completely (at least 7 days). For thin layers, cold temperatures (ambient, substrate, and resin temperatures below 60°F) and increased humidity, the time until the epoxy resin is fully cured may be extended.

Consumption volumes

Total Thickness for Floors and Other Surfaces: 1/16”

- Priming with EPOXY PRIMER: approx. 0.65oz/sqft

- Main Layer: approx. 4oz/sqft

Customer Service: If you have further questions, please contact us by phone, e-mail or use our WhatsApp support.

Note: Please note that due to different lighting conditions and monitors, the colors may not be uniformly displayed.